MichaelB1969

Guru

- Joined

- Oct 15, 2016

- Messages

- 679

- Location

- USA

- Vessel Name

- Speedy Charlotte

- Vessel Make

- Beneteau Swift Trawler 44

Posted this on boatdiesel but figured I'd post here as well to see what people thought:

Would love to see if anyone has guidance here. The prior owner of my boat had a grounding event (there was some superficial fiberglass damage and both props got beat up), and I am in the process of fixing some things that weren´t picked up during the survey.

The starboard engine had a vibration that has since been fixed. The shaft was bent about 15 thousandths. The starboard engine now runs smoothly.

When the starboard engine vibration was fixed, the boat yard also re-aligned (even though I didn´t ask them to) the port engine.

When I picked the boat up, I noticed that the port engine was now bucking pretty badly, especially at low rpm´s. Amazing they didn´t see this. Never working with that yard again.

They pulled the boat out, checked the cutlass bearing, shaft, etc., and said everything looked fine. They spent a good deal of time trying to get the alignment better and the engine wasn´t bucking anymore, but it did have a minor movement between 900 - 1,500rpm.

I was done dealing with them because I had little confidence in them. I ran the boat for half the season, and didn´t spend any time at all in the 900 - 1,500 rpm range.

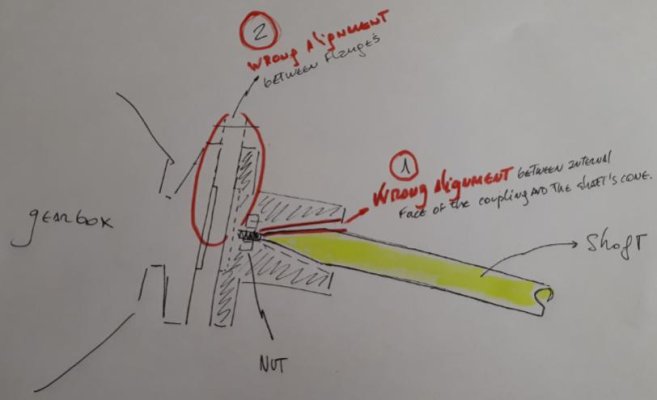

I just brought the boat to a yard I have more confidence in for my annual Volvo service and also asked them to work on eliminating the vibration. They pulled the shaft and determined that it was bent (by 12 thousandths at the center). They had it straightened and aligned the engine, and things improved. There is now a more minor engine movement (they said it´s not really a vibration, but rather an up and down movement) between 980 - 1,050 rpm.

They are turning their attention to the motor mounts at this point, which could possibly have been broken during the grounding. When they sea trialed the boat, they noticed that the inboard mount toward the stern had a lot of movement, and the inboard mount toward the bow had about half the movement.

The outboard mounts were stiffer.

They also notices the mounts were stamped with an "A" on them, and they sent a note to Volvo on the movement and the stamp, and are awaiting a response.

So wondering what people think. The mounts are pricey (around $800 a pop I believe) and there is labor too obviously.

Any thoughts on the movement differences? They checked everything else and didn´t find anything wrong (engine alignment, shaft alignment, cutlass bearing, prop).

Really what I am wondering is this. If the movement is only happening in that tight rpm range where I typically am not operating the boat (I am usually between 1,800 - 2,500), should I even worry about it, or should I just enjoy the boat?

Obviously one can keep going with these things, but I don´t want to throw money at something that isn´t really an issue.

Thanks, and sorry for the long post!

Mike

Would love to see if anyone has guidance here. The prior owner of my boat had a grounding event (there was some superficial fiberglass damage and both props got beat up), and I am in the process of fixing some things that weren´t picked up during the survey.

The starboard engine had a vibration that has since been fixed. The shaft was bent about 15 thousandths. The starboard engine now runs smoothly.

When the starboard engine vibration was fixed, the boat yard also re-aligned (even though I didn´t ask them to) the port engine.

When I picked the boat up, I noticed that the port engine was now bucking pretty badly, especially at low rpm´s. Amazing they didn´t see this. Never working with that yard again.

They pulled the boat out, checked the cutlass bearing, shaft, etc., and said everything looked fine. They spent a good deal of time trying to get the alignment better and the engine wasn´t bucking anymore, but it did have a minor movement between 900 - 1,500rpm.

I was done dealing with them because I had little confidence in them. I ran the boat for half the season, and didn´t spend any time at all in the 900 - 1,500 rpm range.

I just brought the boat to a yard I have more confidence in for my annual Volvo service and also asked them to work on eliminating the vibration. They pulled the shaft and determined that it was bent (by 12 thousandths at the center). They had it straightened and aligned the engine, and things improved. There is now a more minor engine movement (they said it´s not really a vibration, but rather an up and down movement) between 980 - 1,050 rpm.

They are turning their attention to the motor mounts at this point, which could possibly have been broken during the grounding. When they sea trialed the boat, they noticed that the inboard mount toward the stern had a lot of movement, and the inboard mount toward the bow had about half the movement.

The outboard mounts were stiffer.

They also notices the mounts were stamped with an "A" on them, and they sent a note to Volvo on the movement and the stamp, and are awaiting a response.

So wondering what people think. The mounts are pricey (around $800 a pop I believe) and there is labor too obviously.

Any thoughts on the movement differences? They checked everything else and didn´t find anything wrong (engine alignment, shaft alignment, cutlass bearing, prop).

Really what I am wondering is this. If the movement is only happening in that tight rpm range where I typically am not operating the boat (I am usually between 1,800 - 2,500), should I even worry about it, or should I just enjoy the boat?

Obviously one can keep going with these things, but I don´t want to throw money at something that isn´t really an issue.

Thanks, and sorry for the long post!

Mike