Simi 60

Guru

- Joined

- Jul 1, 2016

- Messages

- 5,482

- Location

- Australia

- Vessel Make

- Milkraft 60 converted timber prawn trawler

Anyone used one?

POWERTWIST V Belts | Fenner Drives

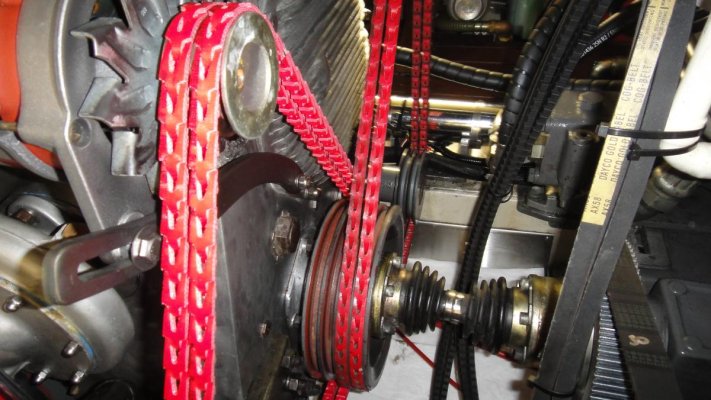

To replace the raw water pump belt on ours requires removing some gear whereas these would not.

Thinking it would make a better spare than a one piece belt.

POWERTWIST V Belts | Fenner Drives

To replace the raw water pump belt on ours requires removing some gear whereas these would not.

Thinking it would make a better spare than a one piece belt.