Mischief Managed

Guru

- Joined

- Oct 24, 2018

- Messages

- 678

- Location

- USA

- Vessel Name

- Mischief Managed II

- Vessel Make

- 1992 Tollycraft 44 CPMY

I'm doing some projects on my boat this Winter and have noticed that the hoses between between the packing glands and the prop shaft tubes are likely original and will be 30 years old next month. I was planning to replace them but was thinking this might be a great opportunity to switch to a dripless seal system while the shafts are pulled. I'd love to have a dry bilge while cruising...

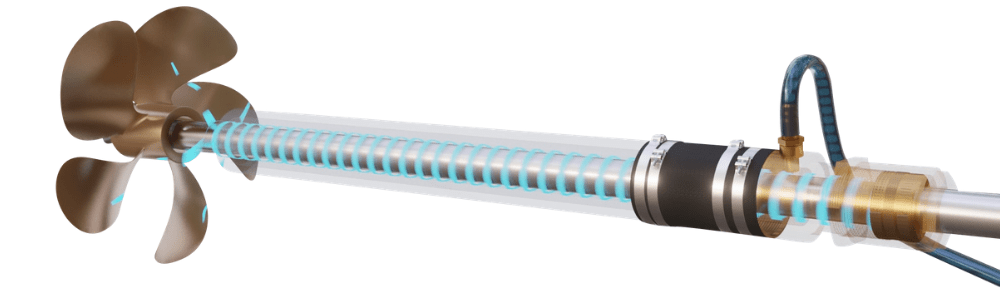

What's a good system to use on a boat that's had packing glands for 30 years? I assume the shafts are not perfect so leaning toward PSS style.

Any reason not to use a dripless system?

What's a good system to use on a boat that's had packing glands for 30 years? I assume the shafts are not perfect so leaning toward PSS style.

Any reason not to use a dripless system?