meridian

Guru

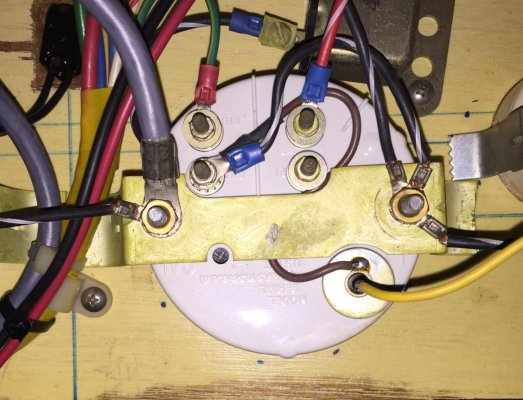

The tach on my port Lehman, driven off the alternator, reads about 150 rpm on the high side. I tried using a screwdriver in the adjusting slot but it is already at the stops to decrease the needle. I can make it read higher but not lower. I can always keep my cheat sheet but I would like to make the tach accurate as the one on the other engine is also off, but by a different number. I usually set the port engine to the known rpm and sync the other one by sound.

Any ideas on how to fix this?

Any ideas on how to fix this?