Waterant

Senior Member

Hi guys,

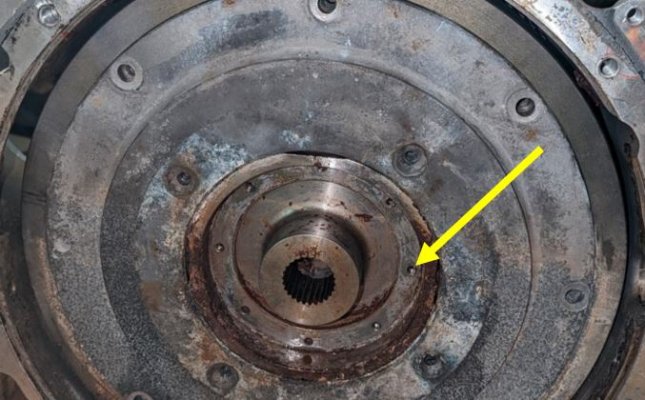

I'm trying to remove a flywheel from Yanmar 6LY2A-STP, and there is a weird-looking dumper plate (or i think it is) in front of the flywheel (see photo).

it's recessed inside the wheel and i can not figure out how to remove it to get to the bolts attaching the flywheel to the crankshaft.

everything i could find online shows the flywheel without the dumper plate or a different kind of the dumper plate bolted on top of the flywheel. this one is recessed inside, and i do not see any obvious ways to get it out of there

any suggestion on how to do this is appreciated.

I'm trying to remove a flywheel from Yanmar 6LY2A-STP, and there is a weird-looking dumper plate (or i think it is) in front of the flywheel (see photo).

it's recessed inside the wheel and i can not figure out how to remove it to get to the bolts attaching the flywheel to the crankshaft.

everything i could find online shows the flywheel without the dumper plate or a different kind of the dumper plate bolted on top of the flywheel. this one is recessed inside, and i do not see any obvious ways to get it out of there

any suggestion on how to do this is appreciated.

Attachments

Last edited: