mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,233

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

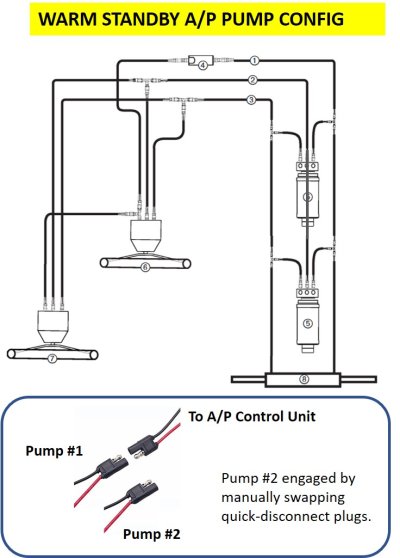

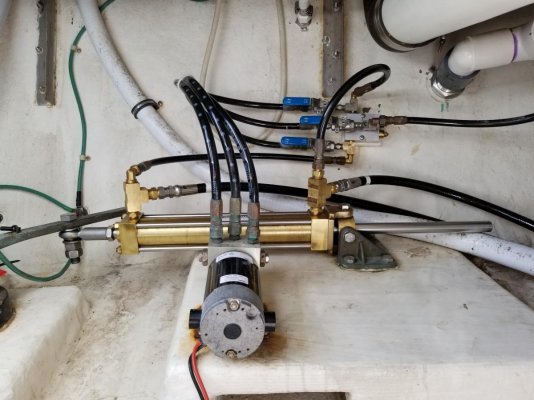

I've ended up with a spare A/P pump. I'd like to install as a warm-standby in case of pump failure. My theory is that if the pump/motor craps out, I'll disconnect wires to old pump and wire to standby pump.

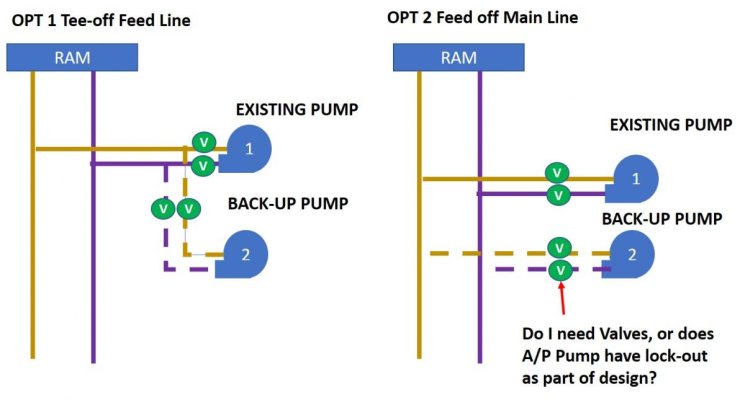

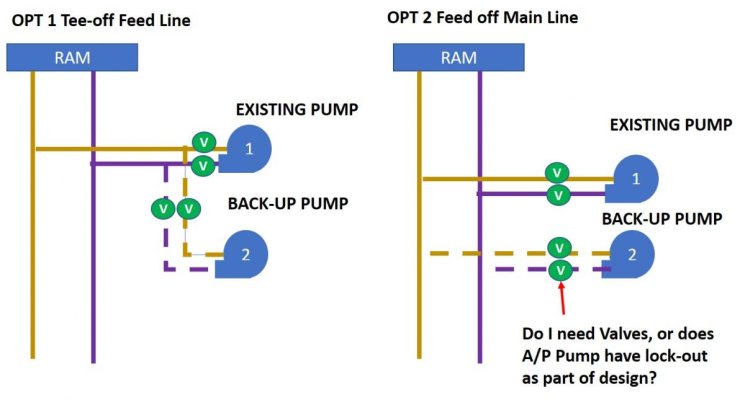

1. What should the plumbing look like? See attached for two options. Option 1 (Tee-off existing likes to existing pump) or Option 2 (Tee off main lines). Option 1 is easier, and I'm not sure it makes any difference. Thoughts?

2. I would think the A/P pump have lock-outs so I really don't need valves to isolate the standby pump. What say the Bigger Brain of TF?

Any other considerations?

Thanks in advance

Peter

1. What should the plumbing look like? See attached for two options. Option 1 (Tee-off existing likes to existing pump) or Option 2 (Tee off main lines). Option 1 is easier, and I'm not sure it makes any difference. Thoughts?

2. I would think the A/P pump have lock-outs so I really don't need valves to isolate the standby pump. What say the Bigger Brain of TF?

Any other considerations?

Thanks in advance

Peter

Last edited: