Snapdragon III

Senior Member

- Joined

- Sep 1, 2016

- Messages

- 415

- Location

- USA

- Vessel Name

- Snapdragon

- Vessel Make

- Custom 56' Skookum trawler

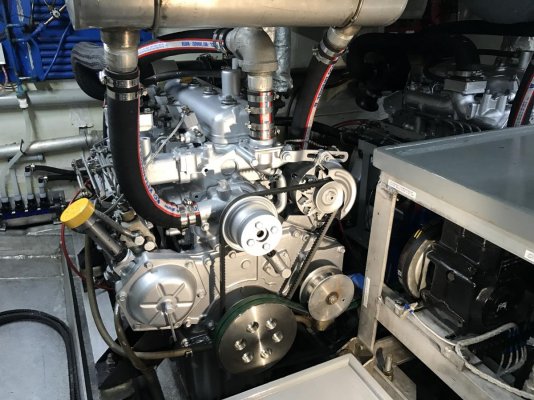

My boat has a double V-belt sheave that is installed on a 1 1/4" keyed shaft that is bolted on the end of the crankshaft of the Starboard main. It drives and accessory shaft that has alternator, fridge compressors, hydraulics, etc off of it. I recently removed the double sheave as part of an engine painting project I just finished. Everything was rusty and nasty and I had a heck of a time getting it off the 1 1/4" shaft. I ended up using a 3 arm gear puller, and heating the sheave with a torch to get it off. After cleaning it all up it slid back on easily. It has two set screws on it one on the key, and one at 90 degrees to it that bites right into the shaft. This weekend we took the boat out for the weekend for the first time since doing the work and after about 3 hours of motoring, the sheave loosened up and slid partially off the shaft, causing the brand new belt to jump off the tensioner, grind it's self up, and make a huge amount of black rubber dust in the engine room I had just spent a ton of time cleaning. When I discovered it after we had anchored, (I had checked the engine room several times, during the trip, but it must have happened right at the end) I took it apart, cleaned off the anti seize I had put on the shaft so it wouldn't get stuck, and put it all back together, tightening the set screws as much as I dared not wanting to strip them, or break off the allen wrench. I checked it a bunch of times on the way home, but never shut off the engine and checked the tightness of the set screws. When I got back to the marina after about 4 hours of crusing, The sheave was loose again, and the set screws were loose!

What is happening?

How should I fix it?

My thoughts are: Should I put some sort of lock tight on the set screws? Should I put some kind of lock tight on the Shaft? Could that be why it was so hard to get apart in the first place? Is it a thermal expansion issue where the sheave is growing more than the shaft as it heats up? Should I heat it in boiling water, put it on, and tighten the set screws with it hot?

Thanks in advance for any good advice. Other than this we had a fun weekend out in the cold. First time pulling crab pots in the snow.

What is happening?

How should I fix it?

My thoughts are: Should I put some sort of lock tight on the set screws? Should I put some kind of lock tight on the Shaft? Could that be why it was so hard to get apart in the first place? Is it a thermal expansion issue where the sheave is growing more than the shaft as it heats up? Should I heat it in boiling water, put it on, and tighten the set screws with it hot?

Thanks in advance for any good advice. Other than this we had a fun weekend out in the cold. First time pulling crab pots in the snow.