Merkinbrumsky

Newbie

- Joined

- Jul 17, 2022

- Messages

- 4

- Vessel Make

- Carver Voyager

Hi all

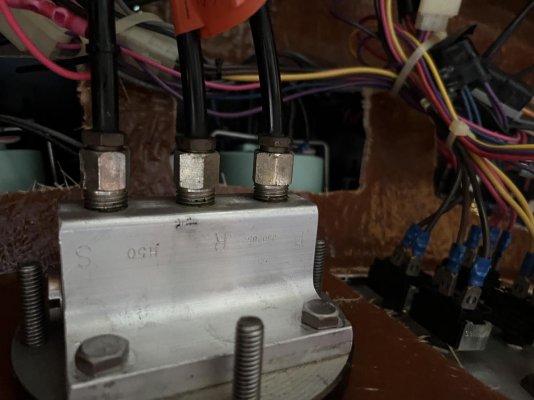

New to the forum. My old hynautic h-50 helm pump has blown a seal at the bridge station. I have a seal kit and am about to remove the pump for a rebuild but one of the old hynautic line fittings is proving stubborn to unscrew. The lines are the original nylon hydraulic lines. Any ideas on how to loosen up the last fitting so I can remove the pump without damaging anything appreciated.

Thanks

Kris

New to the forum. My old hynautic h-50 helm pump has blown a seal at the bridge station. I have a seal kit and am about to remove the pump for a rebuild but one of the old hynautic line fittings is proving stubborn to unscrew. The lines are the original nylon hydraulic lines. Any ideas on how to loosen up the last fitting so I can remove the pump without damaging anything appreciated.

Thanks

Kris