You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reviving a comatose Lehman

- Thread starter N97746

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Nick F

Guru

- Joined

- Sep 2, 2020

- Messages

- 598

- Location

- Canada

- Vessel Name

- Callisto

- Vessel Make

- 1974 Grand Banks 42 Classic, Hull 433

Finally - the mystery is solved! Thanks for this, Mike (N97746) - well found.

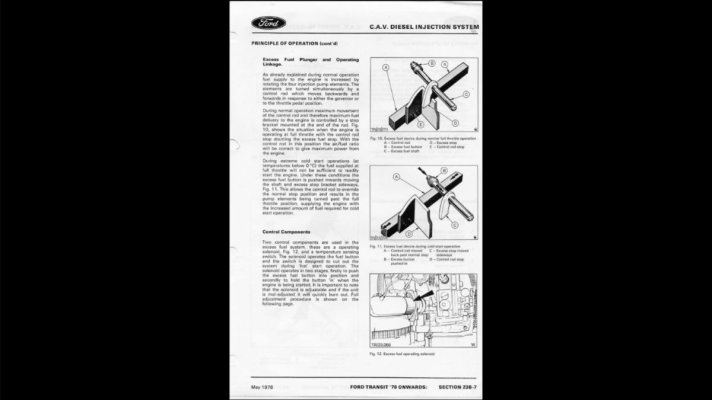

So, some motors just like more fuel to be injected at startup. . .

Is it possible that this is linked to the presence of some air in the injector lines? I doubt it, but how does one explain the difference between motors? Could it be the compression being low when the cylinder walls are dry after some time not running?

Another possibility is that the control rod stop adjustment is different from engine to engine. This is what limits the fuel injection during normal operation and which is bypassed when the cold start is pushed. I think I favour this explanation.

So, some motors just like more fuel to be injected at startup. . .

Is it possible that this is linked to the presence of some air in the injector lines? I doubt it, but how does one explain the difference between motors? Could it be the compression being low when the cylinder walls are dry after some time not running?

Another possibility is that the control rod stop adjustment is different from engine to engine. This is what limits the fuel injection during normal operation and which is bypassed when the cold start is pushed. I think I favour this explanation.

Last edited:

DaveGibson

Veteran Member

- Joined

- Mar 17, 2013

- Messages

- 49

- Location

- USA

- Vessel Name

- Drift Away

- Vessel Make

- 46' Cheoy Lee LRC trawler

Never an issue for my Ford Lehmans

My 1980 Cheoy Lee LRC sat on the hard for 22 years with no maintenance to anything. When I dropped it in, I cranked both engines and both started immediately. 22 year old diesel, no bleeding, no nothing. Not even water in the radiator. I cranked them just to see if they would turn over. Imagine my surprised when they started and I hurriedly shut them down.

I am no mechanic, but I pretty much got everything operational on those engines, including replacing the secondary filters with spin-ons. If the engine will only start with the cold start engaged isn't that indicative of a compression problem? No compression means Dr. Diesel's engine won't start or run. The cold start is supplying the ignition.

Keep in mind that I also drank a lot on the boat.

My 1980 Cheoy Lee LRC sat on the hard for 22 years with no maintenance to anything. When I dropped it in, I cranked both engines and both started immediately. 22 year old diesel, no bleeding, no nothing. Not even water in the radiator. I cranked them just to see if they would turn over. Imagine my surprised when they started and I hurriedly shut them down.

I am no mechanic, but I pretty much got everything operational on those engines, including replacing the secondary filters with spin-ons. If the engine will only start with the cold start engaged isn't that indicative of a compression problem? No compression means Dr. Diesel's engine won't start or run. The cold start is supplying the ignition.

Keep in mind that I also drank a lot on the boat.

Choices

Guru

- Joined

- Apr 16, 2018

- Messages

- 899

- Location

- Montgomery, Tx

- Vessel Name

- Choices

- Vessel Make

- 36 Grand Banks Europa

I have a 135. My cold start sequence is to push start and stop buttons together until oil prs gauge moves, then release the stop button.

reeltime

Veteran Member

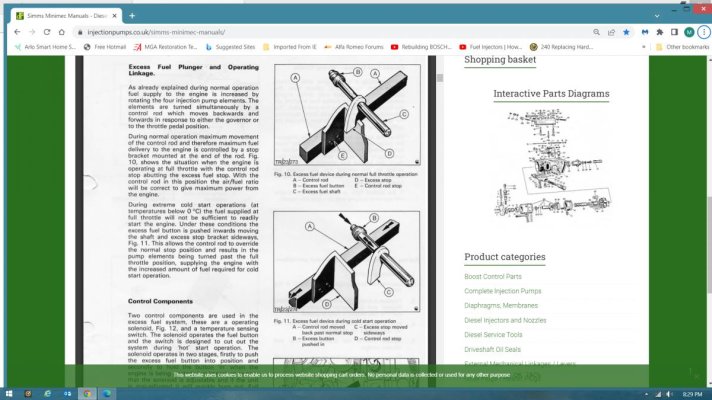

Sounds like the rack is sticking .

This controls fuel flow compared to engine load .

The cold start just overrides the govoner and delivers full fuel until rpm meets throttle setting .

The throttle just determines govenor position not fuel supply .

I think the rack would have a fine coating of rust maybe from sitting with low oil and no splash feed for so long . Take the cover of and gentle move rack control leaver back and forth with a spray of WD40 or the like ,it will probably free up once run again , Cheers

This controls fuel flow compared to engine load .

The cold start just overrides the govoner and delivers full fuel until rpm meets throttle setting .

The throttle just determines govenor position not fuel supply .

I think the rack would have a fine coating of rust maybe from sitting with low oil and no splash feed for so long . Take the cover of and gentle move rack control leaver back and forth with a spray of WD40 or the like ,it will probably free up once run again , Cheers

psneeld

Guru

Never bled the injectors on my Lehman.

Had the whole fuel assembly off at least a dozen times from pipes to injectors.

2 bleed screws on the pump was all the bleeding it ever needed.

Never knew what a cold start option was till I read about it, another item my engine never had or needed.

Had the whole fuel assembly off at least a dozen times from pipes to injectors.

2 bleed screws on the pump was all the bleeding it ever needed.

Never knew what a cold start option was till I read about it, another item my engine never had or needed.

Get rid of the mechanical fuel lift pump they are useless imo install a 12 volt fuel pump solves all priming problems and you just know it’s working, nothing but problems the old diaphragm fuel pumps on Lehmans, cheapest job you can do on a Lehman to bring it into the 21st century with still all the 20th century benefits of a Lehman

ronobrien

Guru

I was a diesel tech for Mack Trucks some years back, when they had full mechanical injection similar to the FL. Once fuel is in the fuel galley of the IP, it is pressurized to 4000+ PSI. This is enough to overcome the injector springs. In hundreds of service procedures I never once had to bleed the injector lines. You do need to be sure that the fuel galley of the IP is fully bled.You have to bleed the injector lines. If there's air in the lines, it compresses, doesn't move the fuel along, and the fuel in the injector never reaches a high enough pressure to overcome the spring loaded valve in the injector. So no fuel to the cylinder.

Just loosen all the tube nuts and bleed all at the same time. Place rags around the injectors. Dish soap and water will clean up the diesel later.

You bleed all at the same time so the pressure is too low for any injector to open. Doing one at a time may cause the engine to start with a tube open and a bigger mess.

As the pressure builds in the fuel gallery near the injector tip, it forces the needle valve open. There needs to be nearly zero air in the line. Otherwise the air just compresses, no fuel moves, no spray, no start.

You may need some heat, too. If compression is low.

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,299

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Give it a shot of ether.

You can really mess up an engine by shooting ether into it. If you must use ether then spray it on a rag and hold the rag by the intake. Better yet fix the engine so it doesn’t need starting fluid.

catalinajack

Guru

When I was a teenager (60 years ago) my father had contracted some dozer work (Cat D8). It was winter. The engine would not start. The owner-operator decided to use ether. He blew the head right off the block.You can really mess up an engine by shooting ether into it. If you must use ether then spray it on a rag and hold the rag by the intake. Better yet fix the engine so it doesn’t need starting fluid.

Nick F

Guru

- Joined

- Sep 2, 2020

- Messages

- 598

- Location

- Canada

- Vessel Name

- Callisto

- Vessel Make

- 1974 Grand Banks 42 Classic, Hull 433

Sounds like the rack is sticking .

This controls fuel flow compared to engine load .

The cold start just overrides the govoner and delivers full fuel until rpm meets throttle setting .

The throttle just determines govenor position not fuel supply .

I think the rack would have a fine coating of rust maybe from sitting with low oil and no splash feed for so long . Take the cover of and gentle move rack control leaver back and forth with a spray of WD40 or the like ,it will probably free up once run again , Cheers

Dear Reeltime:

If you study post #32 you will see that this ("The cold start just overrides the governor and delivers full fuel until rpm meets throttle setting .") is not true.

The governor is already asking for the full fuel because the motor speed (zero) is less than the throttle setting.

As per post #32, the cold start changes the "full fuel" amount (increases it beyond the normal maximum amount per injection).

Regards,

Nick

TowLou

Senior Member

Talking about either.... Its ok in the right amounts. Older cats had a either cold start injection system on some of their machinery. I barely want to use it as only a last resort or for diagnostic purposes.

ronobrien

Guru

Dear Reeltime:

If you study post #32 you will see that this ("The cold start just overrides the governor and delivers full fuel until rpm meets throttle setting .") is not true.

The governor is already asking for the full fuel because the motor speed (zero) is less than the throttle setting.

As per post #32, the cold start changes the "full fuel" amount (increases it beyond the normal maximum amount per injection).

Regards,

Nick

What you are saying is true for a Detroit Diesel. They start in full fuel without any throttle action. Externally injected engines (FL, older Macks, Cats, most Cummins) only get full fuel if you place the throttle in that position. With an externally injected engine (specifically during a low ambient temperature) you hold the throttle at full fuel until it fires.

Well folks, time for an update. After considering the suggestions on the Forum and speaking with Brian at AD I went ahead and bled the injector lines. Actually I started from the temporary fuel tank and again bled everything up to and including the IP. Clear fuel all around. I loosened up all the hard line to injector fittings and cranked the engine for about thirty seconds total. Got fuel from all fittings, then snugged everything back up again.

Went for an engine start, cranked for about thirty seconds in five second bursts and..... nothing, wouldn't even spit. I did see that I was getting white vapor from the exhaust which I assumed was fuel vapor. Even though Brian said to never use the cold start I decided to try that just as I described in the first post. Sure enough just as before after five or six revolutions it fired up into a slow idle then went into full race mode for about two seconds and died. The throttle was about half speed and I never touched it when it was running.

So in a nutshell, only starts when using cold start button, idles for two or three seconds goes to full speed then dies. One other point, I'm using a fuel priming bulb between my temporary tank and the primary filter manifold. It does go soft between engine bursts. Can't remember if it is the same situation on my outboard.

Again thanks for any help of suggestions.

Went for an engine start, cranked for about thirty seconds in five second bursts and..... nothing, wouldn't even spit. I did see that I was getting white vapor from the exhaust which I assumed was fuel vapor. Even though Brian said to never use the cold start I decided to try that just as I described in the first post. Sure enough just as before after five or six revolutions it fired up into a slow idle then went into full race mode for about two seconds and died. The throttle was about half speed and I never touched it when it was running.

So in a nutshell, only starts when using cold start button, idles for two or three seconds goes to full speed then dies. One other point, I'm using a fuel priming bulb between my temporary tank and the primary filter manifold. It does go soft between engine bursts. Can't remember if it is the same situation on my outboard.

Again thanks for any help of suggestions.

twistedtree

Guru

A couple of thoughts:

Try starting with the cold start, but during the whole startup and brief run, keep squeezing the bulb. If it runs then it would seem you have an inability to draw fuel.

When you pulled the head, did you also remove the timing gears and/or cam? I’m wondering if somehow the valves aren’t operating in concert with the piston positions. Same with the IP. Did it come off, and are you certain it is timed in concert with everything?

And the last question would be whether there is good compression.

It’s pumping fuel to the injectors - you have demonstrated that. But you have pushed fuel to the engine with the primer bulb, and it’s still possible that the IP can’t pull fuel on its own.

After that, all that’s left is poor compression, either because the rings are bad, or because there is some massive timing problem that is leaving valves open at the wrong time preventing combustion. Since you had the engine at least partially apart, I’d go back through and review everything you did.

Try starting with the cold start, but during the whole startup and brief run, keep squeezing the bulb. If it runs then it would seem you have an inability to draw fuel.

When you pulled the head, did you also remove the timing gears and/or cam? I’m wondering if somehow the valves aren’t operating in concert with the piston positions. Same with the IP. Did it come off, and are you certain it is timed in concert with everything?

And the last question would be whether there is good compression.

It’s pumping fuel to the injectors - you have demonstrated that. But you have pushed fuel to the engine with the primer bulb, and it’s still possible that the IP can’t pull fuel on its own.

After that, all that’s left is poor compression, either because the rings are bad, or because there is some massive timing problem that is leaving valves open at the wrong time preventing combustion. Since you had the engine at least partially apart, I’d go back through and review everything you did.

I also would be curious as to how it would, or would not run, with constant pressure from squeezing the fuel primer bulb. Unfortunately primer bulb is down below and starter switch is up in the house. if I could get some help, maybe convince the Admiral to give me a hand, I could try that. If that did the trick it might point towards the lift pump not supplying enough fuel, or maybe not.

I only pulled the head. If timing or compression were a problem I don't think I would get that rapid burst of speed. And when it is in that high speed mode it runs dead smooth.

I only pulled the head. If timing or compression were a problem I don't think I would get that rapid burst of speed. And when it is in that high speed mode it runs dead smooth.

SteveK

Guru

- Joined

- Jul 5, 2019

- Messages

- 5,077

- Location

- Gulf Isalnds BC canada

- Vessel Name

- Sea Sanctuary

- Vessel Make

- Bayliner 4588

I think you are on the right train of thought. The lift pump.A couple of thoughts:

Try starting with the cold start, but during the whole startup and brief run, keep squeezing the bulb. If it runs then it would seem you have an inability to draw fuel.

When you pulled the head, did you also remove the timing gears and/or cam? I’m wondering if somehow the valves aren’t operating in concert with the piston positions. Same with the IP. Did it come off, and are you certain it is timed in concert with everything?

And the last question would be whether there is good compression.

It’s pumping fuel to the injectors - you have demonstrated that. But you have pushed fuel to the engine with the primer bulb, and it’s still possible that the IP can’t pull fuel on its own.

After that, all that’s left is poor compression, either because the rings are bad, or because there is some massive timing problem that is leaving valves open at the wrong time preventing combustion. Since you had the engine at least partially apart, I’d go back through and review everything you did.

twistedtree

Guru

I think you are on the right train of thought. The lift pump.

Hand pumping the bulb would really tell you.

CharlieO.

Guru

- Joined

- Sep 21, 2020

- Messages

- 1,558

- Location

- Lake Champlain Vermont, USA

- Vessel Name

- Luna C.

- Vessel Make

- 1977 Marine Trader 34DC

Have you considered putting an electric fuel pump in place of the priming bulb for diagnostic purposes?

ronobrien

Guru

It does represent a small investment but installing a fuel pressure gauge in line just before the IP is quite helpful in diagnosing fuel issues. If you have and maintain proper pressure at the IP the issue would seem to be in a control of the pump, (rack, governor, etc).Well folks, time for an update. After considering the suggestions on the Forum and speaking with Brian at AD I went ahead and bled the injector lines. Actually I started from the temporary fuel tank and again bled everything up to and including the IP. Clear fuel all around. I loosened up all the hard line to injector fittings and cranked the engine for about thirty seconds total. Got fuel from all fittings, then snugged everything back up again.

Went for an engine start, cranked for about thirty seconds in five second bursts and..... nothing, wouldn't even spit. I did see that I was getting white vapor from the exhaust which I assumed was fuel vapor. Even though Brian said to never use the cold start I decided to try that just as I described in the first post. Sure enough just as before after five or six revolutions it fired up into a slow idle then went into full race mode for about two seconds and died. The throttle was about half speed and I never touched it when it was running.

So in a nutshell, only starts when using cold start button, idles for two or three seconds goes to full speed then dies. One other point, I'm using a fuel priming bulb between my temporary tank and the primary filter manifold. It does go soft between engine bursts. Can't remember if it is the same situation on my outboard.

Again thanks for any help of suggestions.

Thinking what I might do next is to temporarily wire the starter button to down below next to the temporary fuel tank. That way I should be able to crank it over while keeping fuel pressure to the IP via the fuel bulb. this I think should rule in or out the lift pump. I do have an inline fuel pressure test gauge, but like any other tool that I need right now, it's an eight hour drive away.

Keep thinking that there is something that I am missing in the engine's signs/symptoms that would point to the problem.

One of the local lobstermen has a two inch thick workshop manual for these engines which he will loan to me later today. Consensus at the town dock this morning was to check the injector timing in case it slipped. Also to look inside the IP to be sure that the throttle is indeed advancing the fuel rack.

Keep thinking that there is something that I am missing in the engine's signs/symptoms that would point to the problem.

One of the local lobstermen has a two inch thick workshop manual for these engines which he will loan to me later today. Consensus at the town dock this morning was to check the injector timing in case it slipped. Also to look inside the IP to be sure that the throttle is indeed advancing the fuel rack.

psneeld

Guru

Still think the easiest is gravity feed the fuel to the injection pump. Quite sure I have heard this for testing and how some have rigged their day tanks permanently.

For <$30 at harbor freight or other online stores ....I made my own out of spare stuff and had it hanging in the engine room next to the engine for troubleshooting.

For <$30 at harbor freight or other online stores ....I made my own out of spare stuff and had it hanging in the engine room next to the engine for troubleshooting.

Attachments

psneeld

Guru

Psneeld, are you saying to run a line directly from the temporary tank to the IP, bypassing the fuel filters ?

Some may try it if they are sure of the cleanliness of the system...but no, you can still gravity feed though either the secondaries or add in a small filter to your test system.

Another quick update. Spoke again with Brian at AD and he recommended that I check the injection pump timing. He agrees with one of the local fishermen that if I'm getting white vapor cloud out the exhaust fuel is going through the combustion chamber but not at the exact right time. Sounds reasonable and think I will try that next.

twistedtree

Guru

Another quick update. Spoke again with Brian at AD and he recommended that I check the injection pump timing. He agrees with one of the local fishermen that if I'm getting white vapor cloud out the exhaust fuel is going through the combustion chamber but not at the exact right time. Sounds reasonable and think I will try that next.

Along the same lines, when you did your valve adjustment, are you sure you adjusted the right valves in conjunction with various engine rotations?

Also, maybe someone familiar with these engines can comment on the inter-dependencies between the cold start mechanism and the normal governed fuel delivery mechanism. Could the normal fuel delivery mechanism be stuck such that it's not delivering fuel, yet the cold start has an alternate mechansim and still works? In other words, is it possible for one to be stuck and the other work OK?

OldDan1943

Guru

- Joined

- Oct 2, 2017

- Messages

- 10,599

- Location

- USA

- Vessel Name

- Kinja

- Vessel Make

- American Tug 34 #116 2008

Another quick update. Spoke again with Brian at AD and he recommended that I check the injection pump timing. He agrees with one of the local fishermen that if I'm getting white vapor cloud out the exhaust fuel is going through the combustion chamber but not at the exact right time. Sounds reasonable and think I will try that next.

I am not associated not with AD nor do I promote my myself as an expert. I think you have been playing with it too long. I think it is time you call in an expert, tell him what you have done while watching over his shoulder. After he proclaims the engine fit as a fiddle, come and tell us what he discovered.

Similar threads

- Replies

- 23

- Views

- 3K