markpj23

Senior Member

- Joined

- Mar 25, 2021

- Messages

- 199

- Vessel Name

- Black Horse

- Vessel Make

- Med Yachts 62

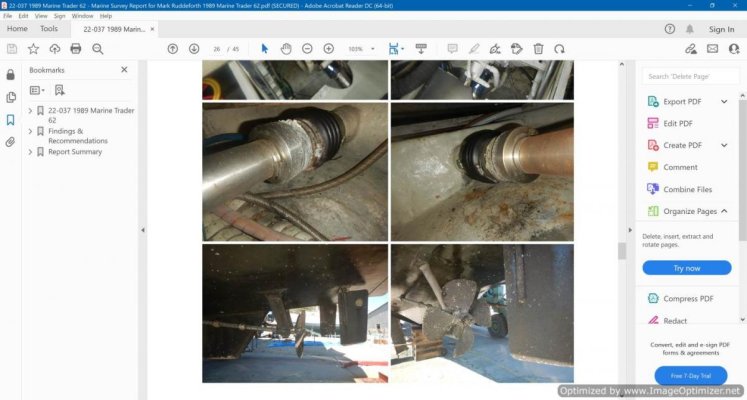

One of the few (yay) items noted on our survey was the shaft seals showing some corrosion / salt / verdigris on them. Of course they're a bit hard to reach but .....

Is this just a simple wipe-it-down and keep an eye on it item, or is something more advisable? I note that there is no sign of a drip or active leak, just the carbon dust stripe below the shaft.

So what's the best way to clean this up? Forgive the picture - it's the best I could extract from a pdf...

Is this just a simple wipe-it-down and keep an eye on it item, or is something more advisable? I note that there is no sign of a drip or active leak, just the carbon dust stripe below the shaft.

So what's the best way to clean this up? Forgive the picture - it's the best I could extract from a pdf...