markrkrebs

Veteran Member

- Joined

- Mar 18, 2020

- Messages

- 47

- Location

- United States

- Vessel Name

- Constellation

- Vessel Make

- Tollycraft 61

My tranny has Hynautic controls with dual pressurizing / charging manifolds. (1985 Tolly 61'). I spent the weekend trying to bleed it.

* There are two charging manifolds (8 lines) so the fwd and reverse lines are pressurized for each transmission, between the slave cylinder and the controls abovedecks. I think this all but precludes a complete purge when bleeding: the top half of the system will never feel a pressure differential, so the fluid will not circulate around. As proof, bleeding from the slave, I can run quarts of clean bubble-free fluid through but still have air up top.

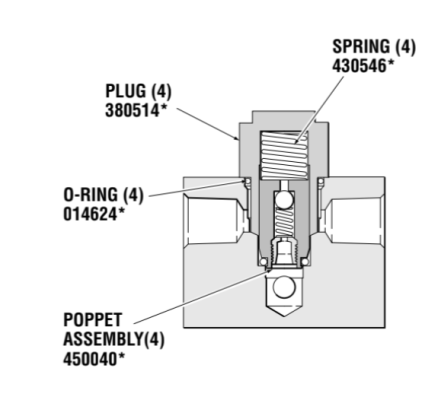

* Ok, so I'll bleed it from the top, I thought. No luck. In one direction it'll bleed but in the other, it's open: no fluid flows in or out. What??? (I think this may mean stuck charging poppet in the reverse half of the leg.

* I say their mechanical drawing (see attachement) has several errors, most egregious the check ball and spring swapped in their positions. And second it's not an interference fit between the brass valve body and aluminum plug, and third the threads in the plug are not so long as to impede flow around the brass valve body. ...and these are all diabolical errors in understanding the damn thing when you're in the bilge at anchor far from succor with radiator fluid all over you.

Any comment? or help?

* There are two charging manifolds (8 lines) so the fwd and reverse lines are pressurized for each transmission, between the slave cylinder and the controls abovedecks. I think this all but precludes a complete purge when bleeding: the top half of the system will never feel a pressure differential, so the fluid will not circulate around. As proof, bleeding from the slave, I can run quarts of clean bubble-free fluid through but still have air up top.

* Ok, so I'll bleed it from the top, I thought. No luck. In one direction it'll bleed but in the other, it's open: no fluid flows in or out. What??? (I think this may mean stuck charging poppet in the reverse half of the leg.

* I say their mechanical drawing (see attachement) has several errors, most egregious the check ball and spring swapped in their positions. And second it's not an interference fit between the brass valve body and aluminum plug, and third the threads in the plug are not so long as to impede flow around the brass valve body. ...and these are all diabolical errors in understanding the damn thing when you're in the bilge at anchor far from succor with radiator fluid all over you.

Any comment? or help?