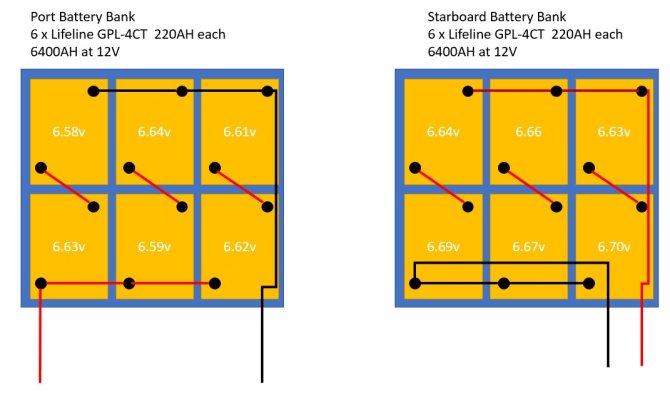

If you determine that the batteries are not off gassing and the charger is not overcharging then load testing would be a good way to go. If one cell in one battery has a problem often a load test will show it.

I have I.D.d some problem batteries simply by recharging them, then disconnecting the " - " side of each battery and then letting the batts. sit for 5 or 10 minutes and then measure the voltage of each.

This will only work if each battery is isolated from the bank and then allowed to sit. It showed one battery that dropped almost 1.5V in that time with no loads, and no connection to the system. Even a 0.5V drop would show a problem.

THe other two batteries showed the same voltage as each other.

Meant at least one cell in that one battery was bad.

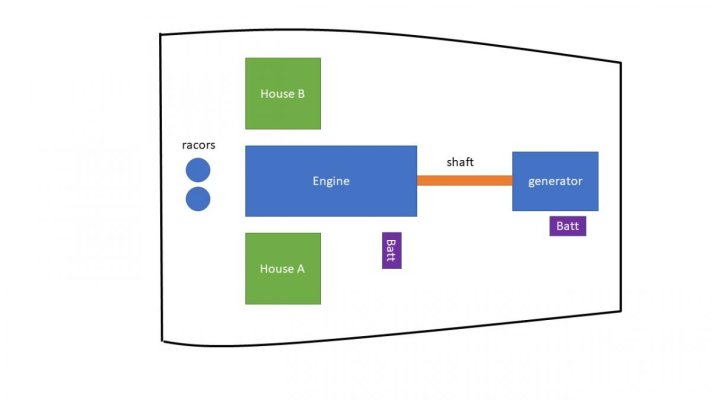

Your mention of a dripless shaft seal that is not dripless brings up a bug a bear to me.

THe shaft seal, dripless or not, is not completely water spray free. Part of my job, when still working, was to rebuild water pumps.

Many used exactly the same type of seal, just bigger. THey do NOT totally and completely block water escape as you are finding.

I found that there was a very fine spray , not much but definitely present, that was thrown and could travel. It is fine enough that you can't see it with a good seal but it was present and could be detected by holding a paper towel close to it for a minute or thereabouts. It would dampen the towel.

THat very fine spray can travel and starting steel parts nearby rusting.

Cover the dripless seal with an old fender cut to suit or some other block with a narrow slit on the bottom so the water spray is stopped and then drops into the bilge. Simple, not pretty maybe, but effective.

THis may be the cause of the rusting you are seeing. The cover will prevent the very fine spray from travelling, slowing any rusting and also dampness in the E.R..