bogranjac1

Senior Member

Any recommendations for solutions/solvents/treatments for flushing transmissions ????

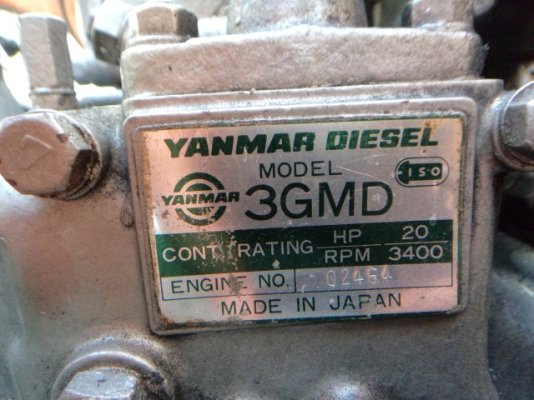

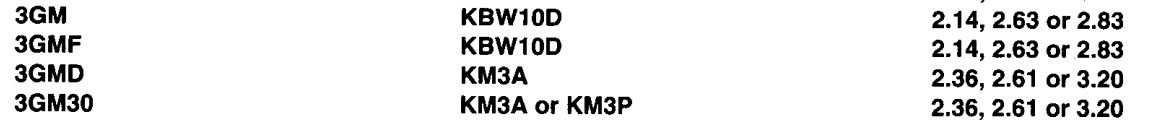

For those with experience with Kanzaki transmissions, mine has developed the dreaded 'shudder' or 'hammer' as the RPM is increased through middle range - 1500-2000 then beyond completely disappears.

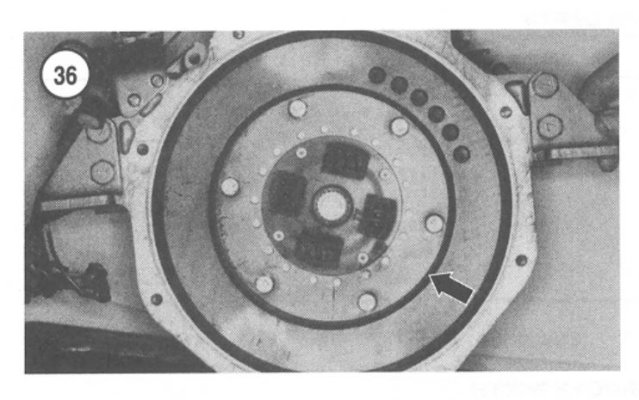

At first I thought it was the cutless bearing then maybe loose engine mounts or incorrect lubricant. Finally tracked it down to what is called 'varnished' cones in the gears. This is where the mating surfaces of the cones have become coated or clogged and only partial engagement occurs.

Was wondering if FLUSHING the transmission with any particular solution/solvent may assist in ridding this 'varnish' or clogging.

Was wondering if FLUSHING the transmission with any particular solution/solvent may assist in ridding this 'varnish' or clogging.

I really do NOT want to remove the transmission and dismantle it if at all possible, although now that I am home from my travels I have an acceptable workshop as a last resort.

regards Brett

links below refer to my problem in detail

J/30 Rhapsody #348: Transmission Disassembly & Clutch Resurface

Kanzaki cone issues... - Cruising Anarchy - Sailing Anarchy Forums

For those with experience with Kanzaki transmissions, mine has developed the dreaded 'shudder' or 'hammer' as the RPM is increased through middle range - 1500-2000 then beyond completely disappears.

At first I thought it was the cutless bearing then maybe loose engine mounts or incorrect lubricant. Finally tracked it down to what is called 'varnished' cones in the gears. This is where the mating surfaces of the cones have become coated or clogged and only partial engagement occurs.

I really do NOT want to remove the transmission and dismantle it if at all possible, although now that I am home from my travels I have an acceptable workshop as a last resort.

regards Brett

links below refer to my problem in detail

J/30 Rhapsody #348: Transmission Disassembly & Clutch Resurface

Kanzaki cone issues... - Cruising Anarchy - Sailing Anarchy Forums