AusCan

Guru

- Joined

- Jul 15, 2012

- Messages

- 3,218

- Location

- Australia

- Vessel Name

- Kokanee

- Vessel Make

- Cuddles 30 Pilot House Motor Sailer

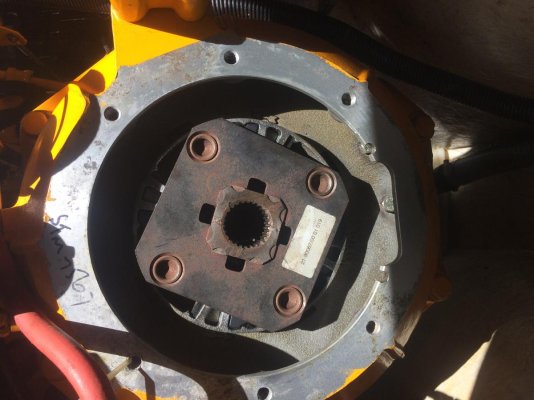

I re-powered about 2 years ago with a 42 hp Vetus diesel (Mitsubishi based) and a ZF-25A gearbox.

The gearbox is a ~7 degree downangle design and a 1.98:1 ratio. The ZF-25A is one size up from what Vetus was originally offering with this engine.

The gearbox was always a little bit rattly when in gear at low rpm (850-1000rpm), although just recently it seems to gotten slightly worse (rattling from 850- 1200 rpm). The rattle is louder than the actual engine noise. Over 1200n rpm it is nice and quiet.

I've heard a variety of opinions from "this is normal" to "change from ATF to a 10/40 engine oil". A search on the web suggests this is a common problem with many gearboxes, but opinions vary considerably as to what to do about it, or if this is anything more than a nuisance noise.

Any suggestions from the TF forum?

The gearbox is a ~7 degree downangle design and a 1.98:1 ratio. The ZF-25A is one size up from what Vetus was originally offering with this engine.

The gearbox was always a little bit rattly when in gear at low rpm (850-1000rpm), although just recently it seems to gotten slightly worse (rattling from 850- 1200 rpm). The rattle is louder than the actual engine noise. Over 1200n rpm it is nice and quiet.

I've heard a variety of opinions from "this is normal" to "change from ATF to a 10/40 engine oil". A search on the web suggests this is a common problem with many gearboxes, but opinions vary considerably as to what to do about it, or if this is anything more than a nuisance noise.

Any suggestions from the TF forum?