Thanks everyone for your help on this. I've done more research and it seems I'm compliant.

I asked my surveyor what rules does Transport Canada follow concerning fuel systems for pleasure craft and he said that they follow ABYC. After my research and consultation with a respected marine consultant, here is what ABYC says about fuel gauges generally and fuel sight gauges in particular:

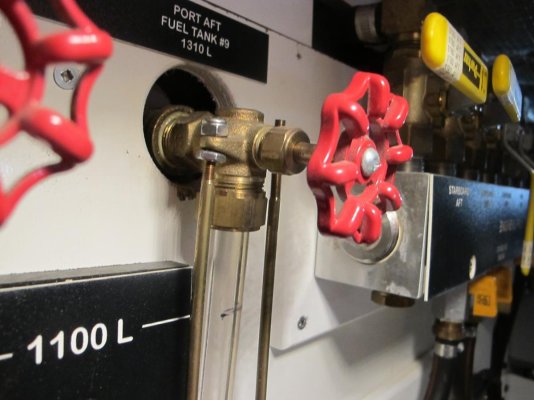

33.5.8 A means to determine fuel level or quantity shall be provided.

33.5.8.1 If a sight gauge is used;

33.5.8.1.1 it shall be equipped with a shutoff valve at the top and at the bottom of the gauge, and

33.5.8.1.2 a warning label shall be placed adjacent to the sight gauge, and

33.5.8.1.2.1 the warning label shall comply with the requirements of H-33.16.

file:///d:/Documents/Boats/ABYC%20Diesel%20fuel%20systems_2005.pdf

Note that the regulations do not "identify" type of material accepted for use in sight tubes. This was pointed out to me by the "respected marine consultant". What's more interesting is the solution suggested to me by my surveyor uses gate valves, which I was advised

SHOULD NOT BE USED FOR FUEL SYSTEMS.

So I looked the subject further and came up with detailed schematics on sight gauges from John Moncrieff.

https://www.johnmoncrieff.co.uk/wp-content/uploads/2017/08/G22-Quickmount-Datasheet.pdf

They use either borosilicate glass or acrylic tubes in their sight gauges.

I have scoured the web and find that acrylic and borosilicate glass are used for sight tube material. Each have their advantages and disadvantages. Glass is more tolerant to high temperatures, but of course is less tolerant of pressures and mechanical shock, as compared to acrylic which is less tolerant to high temperatures, but more tolerant of pressures and mechanical shock.

A product which is not discussed is Teflon tubing. Teflon tubing is temperature rated to 260 C (source:

PTFE Tubing (PolyTetraFluoroEthylene) from NORELL®), higher than acrylic which is rated to 143-148 C (280-290F, source:

https://www.copeplastics.com/polycarbonate-tubing.html).

So why not use Teflon? You can fry eggs on teflon frying pans. I can easily source Teflon although it’s considerably more expensive than polyethylene, it’s still a more affordable solution than industrial sight gauges that may not be easily retrofitted into existing tank/engine room situations. If there is a rigidity issue with Teflon (it’s highly flexible) it can be shielded in aluminum pipe, with milled grooves for reading.

All I have for now.

Jim