toocoys

Guru

Does this look normal?

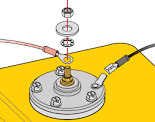

They removed all of our two year old gas through the fuel sending unit hole, and had to disconnect it. Upon reinstallation, we put 50g gas in a 300g tank and it’s read empty ever since.

So either the sending unit was connected improperly, or our sending unit doesn’t go all the way to the bottom of the tank. Which is nice to know that there is a reserve.

I’ve searched for wiring diagrams for VDO sending units but there are quite a few different ones.

They removed all of our two year old gas through the fuel sending unit hole, and had to disconnect it. Upon reinstallation, we put 50g gas in a 300g tank and it’s read empty ever since.

So either the sending unit was connected improperly, or our sending unit doesn’t go all the way to the bottom of the tank. Which is nice to know that there is a reserve.

I’ve searched for wiring diagrams for VDO sending units but there are quite a few different ones.