Arthurc

Guru

Hi,

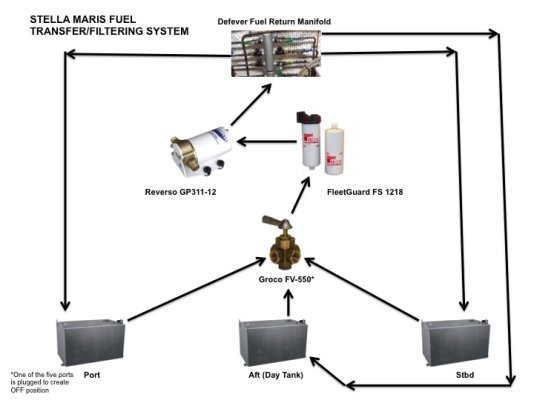

I am designing a revamped fuel system and wanted to get some input from this group. Attached is currently what I am thinking. Arrows indicate direction of flow, I haven't gone so far as to show where each valve goes but that's a next step. Each tank would have its own polishing system on a timer running periodically, since they will be automatic I am wondering if pressure gauges makes sense on them as well so I can remotely monitor if a filter needs changing?

Also note both the Genset and Main have fuel filter systems, I just need to get on the boat to document what they are.

New to this so any feedback of advice would be appreciated.

Arthur

I am designing a revamped fuel system and wanted to get some input from this group. Attached is currently what I am thinking. Arrows indicate direction of flow, I haven't gone so far as to show where each valve goes but that's a next step. Each tank would have its own polishing system on a timer running periodically, since they will be automatic I am wondering if pressure gauges makes sense on them as well so I can remotely monitor if a filter needs changing?

Also note both the Genset and Main have fuel filter systems, I just need to get on the boat to document what they are.

New to this so any feedback of advice would be appreciated.

Arthur