Marco Flamingo

Guru

- Joined

- Jan 7, 2020

- Messages

- 1,111

- Location

- United States

- Vessel Name

- CHiTON

- Vessel Make

- Tung Hwa Clipper 30

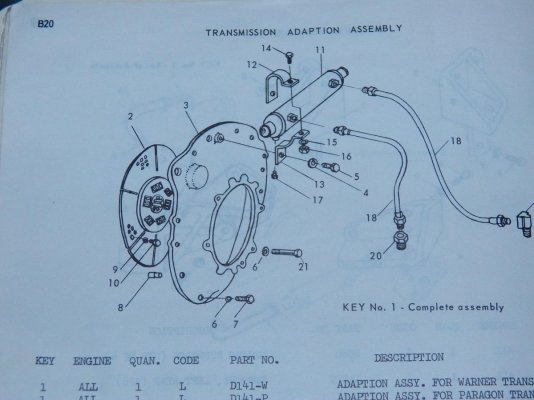

Okay, I had to resort to looking at my old Lehman Operator and Parts Manual (i.e., I read the instructions). If I understand correctly, in the picture that I linked above, the damper plate can be seen, but not removed until the "adapter" plate (key #3in the picture below) is removed. That is the plate that I loosened in order to drain the rusty sludge. When I went in with my endoscope the next day, the bottom of the flywheel casing was damp, but no more sitting liquid, so I dried with a heat gun and then went ahead and installed the starter (which worked perfectly). Still need to get into the damper plate and clean things out.

Do I have it correct that the "all-thread method" of exposing the damper plate is by removing the adapter plate bolts and putting in enough all-thread to support the tranny but not so many as to preclude the removal of the damper plate between the all-thread?

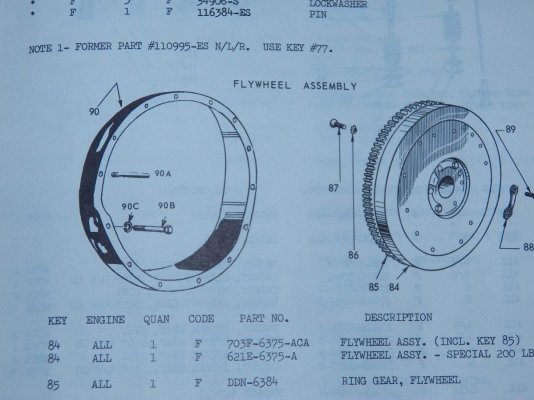

I confirmed something else about my engine. The PO said that it had a heavy flywheel which made the little 4 cyl. Lehman run smoother. Turns out my engine does have the optional larger casing (key #90) and the #200 flywheel (part #621E-6275-A). I thought that the big flywheel was only an option used on the 6 cyl. 120.

Do I have it correct that the "all-thread method" of exposing the damper plate is by removing the adapter plate bolts and putting in enough all-thread to support the tranny but not so many as to preclude the removal of the damper plate between the all-thread?

I confirmed something else about my engine. The PO said that it had a heavy flywheel which made the little 4 cyl. Lehman run smoother. Turns out my engine does have the optional larger casing (key #90) and the #200 flywheel (part #621E-6275-A). I thought that the big flywheel was only an option used on the 6 cyl. 120.