socalrider

Guru

- Joined

- Feb 14, 2020

- Messages

- 1,011

- Location

- usa

- Vessel Name

- SEA WOLF

- Vessel Make

- 1979 CHB 41 Trawler

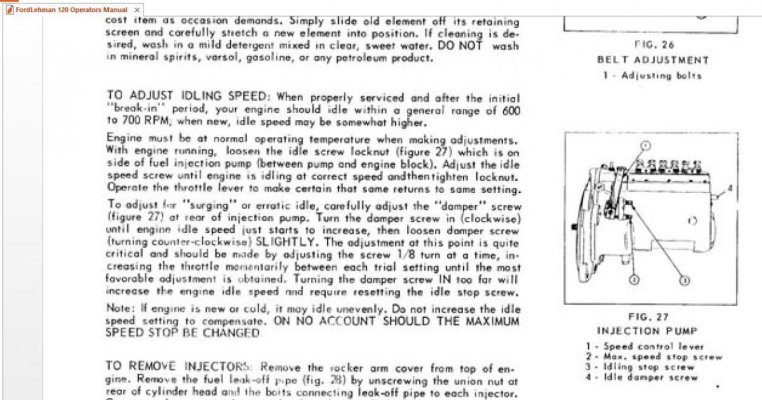

My starboard FL120 is idling at 850-900 rpm; trying to bring that down to 600-700 to match the port engine. I have the Simms injection pump with the idle screw adjustment (versus screw/locknut stops on the control cable for some older versions).

I’ve started them up, let them settle, backed out the surge damper screw, then loosened the locknut and adjusted the screw on the idle speed adjuster. To no discernible effect on either engine, either way.

Any ideas what I’m doing wrong?

I loosened and removed the Morse cable to make sure it wasn’t the culprit.

One other potential clue: I just re-plumbed the entire fuel system, changed and bled the filters, and removed lift pumps, replaced with Warboro units. I don’t remember idle speed being this high before.

I’ve started them up, let them settle, backed out the surge damper screw, then loosened the locknut and adjusted the screw on the idle speed adjuster. To no discernible effect on either engine, either way.

Any ideas what I’m doing wrong?

I loosened and removed the Morse cable to make sure it wasn’t the culprit.

One other potential clue: I just re-plumbed the entire fuel system, changed and bled the filters, and removed lift pumps, replaced with Warboro units. I don’t remember idle speed being this high before.