Okay, here we go. Others are discussing the specifics of and adding to cooling system. I am discussing the basics of a cooling system the wisdom of identifying hull valves and associating them with the various systems onboard the boat. Then, my concluding remarks of the advantages of analog read outs.

First maybe it was just a mis-statement.... gate valves? They are for isolation not for throttling. Globe valves are designed to throttle the flow. Ball valves, (squinting my eyes in emotional pain) in theory they too should be for isolation only. In practice..... well let's just say some folks dont understand what "isolation" means.

Analog gauges..... IMO keep them if at all possible. If you question the accuracy of the gauges, you can either buy new ones or send yours out for repair and calibration. If you have the original analog gauges checked, you know the will fit back in without making new holes. On the face of the gauges there should be the name of the manufacture.

Prelude or apology for the next part: I am not an expert nor a guru. At best, I try to be a "get along."

I am not purposely starting out at the 1st or 2nd grade level. I am attempting to put down on paper, my thoughts as the flow through and out of my feeble, addled, old mind.

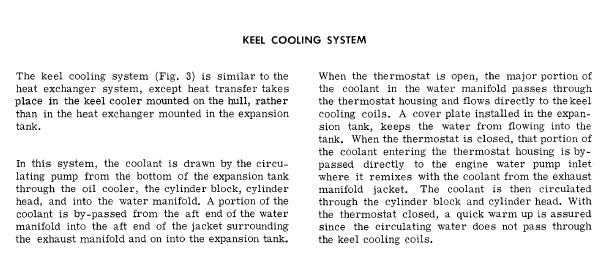

Based upon the pictures, I would be surprised if those fins are keel coolers. They appear to be fins for active stabilizers or some sort of anti-roll device. When you had the boat out of the water, you did not see something that looks like tubular radiator tucked into a pocket of the hull? That is what I would expect and look for, when looking for a keel cooler.

For now, let's assume those are active stabilizers and those are a good thing to have.

Next, go inside and look for the connections to and from those fins. If you see hydraulic ram and hydraulic hoses, they are part of the active stabilizer system and have nothing to do with the cooling system.

We are now back to square 1. One nice thing about square 1, we know where we are.

Have you tried to contact the builder of the boat? IF the company is still around, you can ask some basic questions about the boat. MAYBE then still have some records such as, did it have a keel cooler. Did it have active stabilizers. Perhaps a member of this man's estate can look through the PO's library for some sort of system documentation associated with the boat??

When you haul the boat again or if you are really curious ..... you can do a "short haul". They will keep the boat in the slings as you do a walk around investigating and plot the hull openings. Plot out the location of all the hull openings on two sheets of paper, (put an arrow indicating the pointie end of the boat) one piece of paper for port port side of the bottom and one for starboard side of the bottom. Dont forget those opening on the sides at or above the water line. Make no attempt to identify any of them, beyond the presence and location of the keel cooler. Take pictures too. Personally, I would rely on the drawings..... once you are satisfied with the drawings, put the boat back into the water. Armed with the drawings, drop down into the bilges, find ONE easily recognized hose connected to an easily identified hull opening and system. Let's just start from the stern. Locate it and identify it on the paper. Dont rely on your memory. Document, document, document. Stay on one side, example, the aft port side. When you have documented all hull opening and equated the hull valves to the hull openings on the port side, start over from aft and do it all again for the starboard side, always writing on that paper what you think is correct. You can start over if necessary. Eventually you will have all the hull penetrations identified on paper. Hull openings and hull valve will never move.

Dont worry, for now, about the keel cooler connections. That will sort itself out as we go. After you identify all the hull penetrations on paper ..... you can sit down, stare at the paper and review them in your mind. Please dont be afraid to ask for yard help or another boater.... for a hands-on review.

I know on my Nordhavn, I had more hull penetrations than average boat. The hull valves for the keel cooler were not what one would have expected to find. As I recall, they did not have a handle on the keel cooler hull valves. They were wrench operated, to avoid foolish mistakes, and most definitely meant to be TOTALLY open or factory adjusted. Their settings are not meant to be disturbed. The hoses were much larger in diameter than any other hoses. IF you have adjusted their position return them to the original position. Please tell me, you did not adjust these valves.

The more time you spend on the boat investigating the hull valves, the easier it will be to recognize the hull valves, and their associated systems, either during normal maintenance or emergencies.

Remember, excluding the galley and shower and other sink drains system, there is an 'in and out'. The "in" will be below the water line, the "out" well, that's up for discussion. Most "outs" will be at or above the water line.

IF you have a keel cooler, it is totally immersed in the water so the 'in' and 'out' connections will be below the water line and connected to the keel cooler.

If I have offend you with this simplistic presentation, please know, that was not my intention. While I was explaining it to you, I was explaining it to myself. Next month I will turn or become 75 years old and I am fast becoming dumber than a rock.

Now I will take questions. There is coffee and donuts at the back of the room.

(Daymn, I hope I explained it properly.) If I mis-said something, or totally wrong, point it out. Some will point out, I did not understand the question.... Perhaps, you did not understand what I wrote. May I thank you for reading this.

Once we get everything back to factory specs, others can discuss adding or removing items from the cooling loop. I did see one very well presented cooling system drawing indicating what he, rightfully, thought would be prefect.

Conclusions and recommendations:

IMO, I seriously suspect you have an active stabilizer system.

Do a quick haul, plot out all the hull openings on paper, and look for keel cooler(s) tucked into pocket(s), or indentations, of the hull. If you cant find them, ask for help from a person who works on boats. "Hey, I am new to this boat and I have been told, I have keel coolers. I cant seem to find them, point them out to me, please."

Ignorance is curable, stupidity..... not so much. Make for the life boats and take your own PFD.

Contrary to what folks say, there actually are 'really dumb questions' but at least, you are smart enough to ask them, expanding your knowledge. The dumbest question is the unasked question.

Once upon a time, I remembered the thickness of the tubes of my Nordhavn keel cooler. Lemme tell you, they were very thin. That is why the keel coolers are protected in hull pockets. (Dont ask me why I thought it was necessary to remember that wall thickness, I forgot why.)

My brain hurts. I'm going to bed.

![IMG_2044[1].jpg](/data/attachments/68/68391-91dd3b33bfbc56f4a2a65126e6c1af46.jpg)

![IMG_2043[2].jpg](/data/attachments/68/68430-5a12ae57b1f443a663a3ceb820f308d8.jpg)

![IMG_E2049[1].jpg](/data/attachments/68/68466-d0c83a9c33b0a29fe22c85c4daf6457d.jpg)