Waterant

Senior Member

As my DIY rebuild of Yanmar 6LY went into the "field testing" phase, I wanted to document and share my next engine-related project of getting the fuel consumption data into the Nmea 2000 network, and having it shown on the chart plotter.

The reason for adding this feature

2x 370HP diesel engines drink a considerable amount of fuel, and I want to know what RPM I have to keep in the current conditions for the best MPG. Because the savings (or waste) can be in $100s if not $1000s during a single boating season.

The existing options

I want this data available in Nmea 2000 network and found only 2 options available:

1) A well-known Maretron set. The system will require a fuel flow monitor and 2x fuel flow sensors for each engine. This will cost ~$1200 per engine. Total $2400+ for two engines. And, I think, this will also require a Maretron unit to program and set everything up, so the total cost will be close to $3000.

2) Another option is an unknown unit from Eastern Europe called Delta PN 100 flowmeter. That company supplies the European trucking and generator industry with flow meters and does not advertise to boaters because that market is much smaller and boaters do not buy those units in bulk.

Their monitors fit my requirements perfectly and the total cost of everything to install, program, and use the unit is less than half of Maretron or 1/3rd for a two-engine configuration. A saved $2000 will buy a lot of diesel.

I already used the first version of this unit 4 years ago on my single-engine trawler, and the data was only partly useful. If I connect to the unit with a computer (it has a USB interface), I got very precise consumption data for a set period of time: supply, return, and the difference. It was checked against my fill-ups and was spot on.

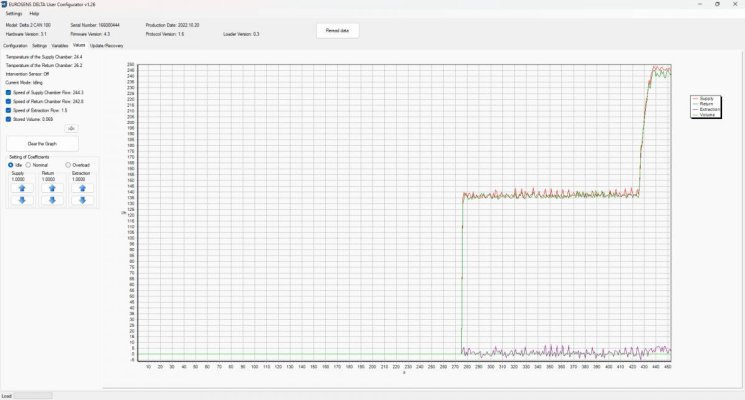

But the instant consumption data sent to Nmea 2000 network, which was the most interesting to me, was useless because it fluctuated from anywhere from 0 GPH to 10 GPH every second. They sent me multiple firmware upgrades, which did not help much. The problem was with sending the instant data into the Nmea network instead of averaging it for a few seconds before sending. I sold that old boat at that time so that exercise ended in 2019.

With a new boat, I decided to give them another go, and they assured me the current version included a user-adjustable averaging setting which solved the instant consumption data issue I was having.

The total cost of the whole system for two engines was $795 USD

Shipping to Canada was $221 USD

For a total of $1016

Here is the photo of what I received.

(only one sender unit is shown, but i've got 2 of them for two engines)

Each unit has 4 connections:

- Fuel In

- Fuel Out

- Return In

- Return Out

and will record the fuel supplied to the engine and fuel returned from the engine to the tank and calculate the difference. That difference is sent to Nmea 2000 network as the current fuel consumption number.

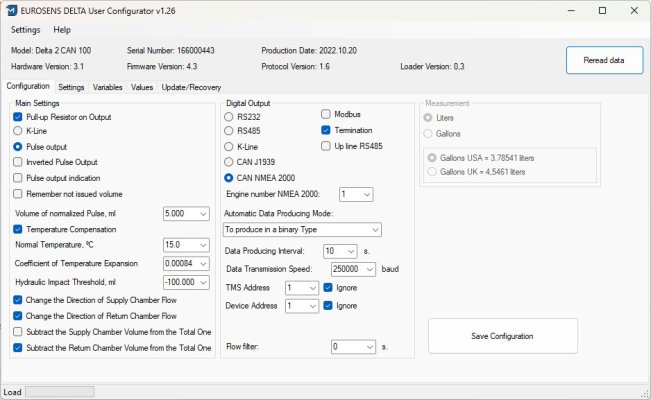

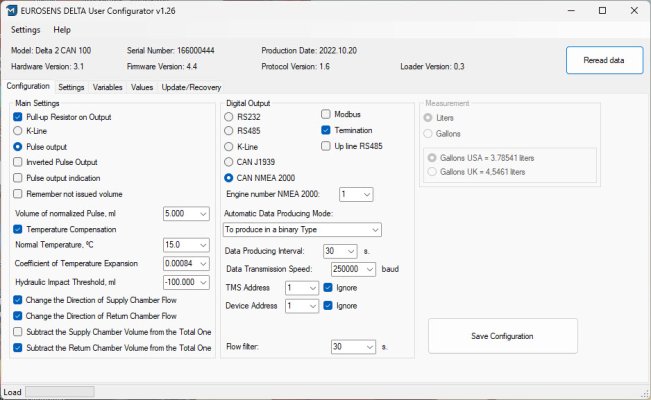

This new version also allows users to adjust the averaging time to calculate this consumption number and I plan to set it to something between 15 and 30 seconds.

I also attached the specs and manual for this unit which I received in 2019.

I did not get the new one yet, but it will be very similar.

Delta PN 100 flowmeter manual

If the latest version of this unit and firmware will work as expected, it has great potential to solve the problem of getting the precise fuel consumption data for older diesel engines without rail injectors as a much less expensive and easier-to-install option.

As a part of this upgrade, I will also be installing Nmea 2000 network and connecting the existing older Raymarine equipment to Nmea 2000.

Let me know if you are also interested in details on this part.

I'll keep you posted on the installation and testing.

The reason for adding this feature

2x 370HP diesel engines drink a considerable amount of fuel, and I want to know what RPM I have to keep in the current conditions for the best MPG. Because the savings (or waste) can be in $100s if not $1000s during a single boating season.

The existing options

I want this data available in Nmea 2000 network and found only 2 options available:

1) A well-known Maretron set. The system will require a fuel flow monitor and 2x fuel flow sensors for each engine. This will cost ~$1200 per engine. Total $2400+ for two engines. And, I think, this will also require a Maretron unit to program and set everything up, so the total cost will be close to $3000.

2) Another option is an unknown unit from Eastern Europe called Delta PN 100 flowmeter. That company supplies the European trucking and generator industry with flow meters and does not advertise to boaters because that market is much smaller and boaters do not buy those units in bulk.

Their monitors fit my requirements perfectly and the total cost of everything to install, program, and use the unit is less than half of Maretron or 1/3rd for a two-engine configuration. A saved $2000 will buy a lot of diesel.

I already used the first version of this unit 4 years ago on my single-engine trawler, and the data was only partly useful. If I connect to the unit with a computer (it has a USB interface), I got very precise consumption data for a set period of time: supply, return, and the difference. It was checked against my fill-ups and was spot on.

But the instant consumption data sent to Nmea 2000 network, which was the most interesting to me, was useless because it fluctuated from anywhere from 0 GPH to 10 GPH every second. They sent me multiple firmware upgrades, which did not help much. The problem was with sending the instant data into the Nmea network instead of averaging it for a few seconds before sending. I sold that old boat at that time so that exercise ended in 2019.

With a new boat, I decided to give them another go, and they assured me the current version included a user-adjustable averaging setting which solved the instant consumption data issue I was having.

The total cost of the whole system for two engines was $795 USD

Shipping to Canada was $221 USD

For a total of $1016

Here is the photo of what I received.

(only one sender unit is shown, but i've got 2 of them for two engines)

Each unit has 4 connections:

- Fuel In

- Fuel Out

- Return In

- Return Out

and will record the fuel supplied to the engine and fuel returned from the engine to the tank and calculate the difference. That difference is sent to Nmea 2000 network as the current fuel consumption number.

This new version also allows users to adjust the averaging time to calculate this consumption number and I plan to set it to something between 15 and 30 seconds.

I also attached the specs and manual for this unit which I received in 2019.

I did not get the new one yet, but it will be very similar.

Delta PN 100 flowmeter manual

If the latest version of this unit and firmware will work as expected, it has great potential to solve the problem of getting the precise fuel consumption data for older diesel engines without rail injectors as a much less expensive and easier-to-install option.

As a part of this upgrade, I will also be installing Nmea 2000 network and connecting the existing older Raymarine equipment to Nmea 2000.

Let me know if you are also interested in details on this part.

I'll keep you posted on the installation and testing.

Attachments

Last edited: