Keith

Guru

- Joined

- Oct 5, 2007

- Messages

- 2,715

- Vessel Name

- Anastasia III

- Vessel Make

- Krogen 42

I had developed a little fuel weep in my Starboard fuel tank. This is the original tank on a 1986 Krogen 42, hull #99. This was more of a nuisance than a problem about ½ cup of fuel would leak out per week, and I was using sorbent pads to catch it. The fuel was actually coming out of the forward bulkhead in the engine room and originally I had thought it was leaking from one of the fuel filters which are right there. Once I eliminated this, I knew the fuel was coming from the tank somewhere, running forward, and exiting from behind the bulkhead.

*

I hired a local fuel tank repair guy to fix this problem. We first pumped all the fuel to the other tank, and then he cut three additional ports so that he could access each area of the tanks. There are four baffled sections, and I only had one inspection port forward. The main thing we found was rust on the upper portions of the inside of the tank, where fuel usually never gets, since I dont ever fill that high. This rust would fall off to the bottom of the tank, making a layer of crud down there. There was very little slime/crud other than that, so he scraped the bottom of the tank to clean out all this stuff.

*

He then cleaned the inside of the tanks with a solvent. Im not sure what he used, but it smelled like MEK or maybe lacquer thinner. I also smelled alcohol, so maybe he used a mix. Naphtha would also work well. While doing all this, he hooked up a blower to the fill on the deck so it would suck the air out through the tank. We left this in place throughout the project. He essentially used a cardboard tube to make a riser out of the fill, and then put the intake hose from the blower over that.

*

Once the tank had been solvent cleaned, he used an air grinder with some little 3 disks, maybe 60 grit to clean the metal down to bare and shiny. He then cleaned with solvent again.

*

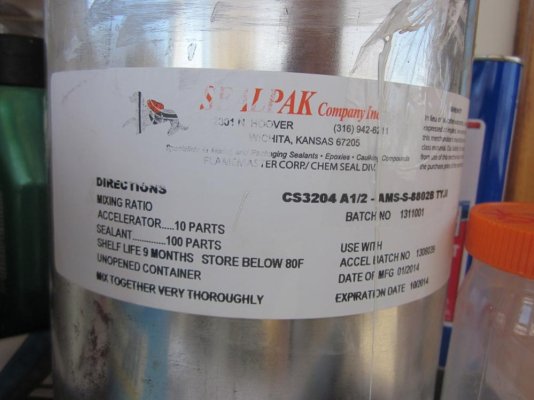

He coated the inside of the tank with some coating he painted on, ended up gray. Coated the entire tank from the bottom up to within about 4 of the top. He was very secretive about what he used, even removing the labels from the cans before bringing them to the boat. He did say it was a fuel tank lining used in the aviation industry.

*

Here is a great .pdf file that explains aviation fuel tank sealers and lists three suppliers:

http://www.vansairforce.net/articles/tank_sealant.pdf

*

Another good one, an aviation fuel tank sealer is at: http://www.sacskyranch.com/proseal.htm PPG Aerospace: http://tinyurl.com/ypwduq

*

*

Searching the internet for aviation fuel tank coating, diesel tank repair or diesel tank lining will bring up other various repair materials. Some are designed to use inside a tank; some are for outside repair. Here are a few links:

*

http://www.nationalsealants.com/Index.html http://www.hexaflex.co.uk/tuffcote.html http://prp-porstore.com/merchant.mvc?Screen=CTGY&Category_Code=TankSealers

http://www.pplmotorhomes.com/parts/caulks-sealants/40754.htm

http://www.piperepair.net/index.html

In any case, call the manufacturer to discuss the use with them.

*

Another candidate comes from www.thinfilmtech.net. They have a product called GasPruf that is designed to line / remediate pipelines, petroleum tanks, etc. Its basically an epoxy. Here is a note from their spec sheet:GasPruf 130<sup>tm</sup>is a unique blend of liquid polymers and proprietary curing agents which is able to displace water or hydrocarbons such as gasoline or diesel fuel from wetted surfaces in order to make a permanent bond. The formulation is solvent-free to ensure safety and maximum technical performance. Kevlarä* fibers are incorporated for reinforcement and viscosity management to achieve high application rates -even under hydrocarbon liquids!

*

I also imagine that you could use things like JB Weld or Splash Zone on the outside of the tank, if you can access it and find the leak.

*

The seals for the new inspection ports were interesting. They were stainless steel, with a flat plate for the outside and two half-rings for the inside of the tank. He used them as a template to drill the holes outside the inspection port. He then threaded the bolts into the two half rings, sealing the threads with epoxy. He then made a gasket for the inside and outside of the tank, installed the two half rings inside with their gasket, then the outside plate with the gasket. The reason for the two half-rings was so that they could be passed through the hole. See: http://www.seabuilt.com/

*

The repair seems to be working perfectly. The leak is repaired and I have a new set of inspection ports if I ever need to get in there again.

*

I hired a local fuel tank repair guy to fix this problem. We first pumped all the fuel to the other tank, and then he cut three additional ports so that he could access each area of the tanks. There are four baffled sections, and I only had one inspection port forward. The main thing we found was rust on the upper portions of the inside of the tank, where fuel usually never gets, since I dont ever fill that high. This rust would fall off to the bottom of the tank, making a layer of crud down there. There was very little slime/crud other than that, so he scraped the bottom of the tank to clean out all this stuff.

*

He then cleaned the inside of the tanks with a solvent. Im not sure what he used, but it smelled like MEK or maybe lacquer thinner. I also smelled alcohol, so maybe he used a mix. Naphtha would also work well. While doing all this, he hooked up a blower to the fill on the deck so it would suck the air out through the tank. We left this in place throughout the project. He essentially used a cardboard tube to make a riser out of the fill, and then put the intake hose from the blower over that.

*

Once the tank had been solvent cleaned, he used an air grinder with some little 3 disks, maybe 60 grit to clean the metal down to bare and shiny. He then cleaned with solvent again.

*

He coated the inside of the tank with some coating he painted on, ended up gray. Coated the entire tank from the bottom up to within about 4 of the top. He was very secretive about what he used, even removing the labels from the cans before bringing them to the boat. He did say it was a fuel tank lining used in the aviation industry.

*

Here is a great .pdf file that explains aviation fuel tank sealers and lists three suppliers:

http://www.vansairforce.net/articles/tank_sealant.pdf

*

Another good one, an aviation fuel tank sealer is at: http://www.sacskyranch.com/proseal.htm PPG Aerospace: http://tinyurl.com/ypwduq

*

*

Searching the internet for aviation fuel tank coating, diesel tank repair or diesel tank lining will bring up other various repair materials. Some are designed to use inside a tank; some are for outside repair. Here are a few links:

*

http://www.nationalsealants.com/Index.html http://www.hexaflex.co.uk/tuffcote.html http://prp-porstore.com/merchant.mvc?Screen=CTGY&Category_Code=TankSealers

http://www.pplmotorhomes.com/parts/caulks-sealants/40754.htm

http://www.piperepair.net/index.html

In any case, call the manufacturer to discuss the use with them.

*

Another candidate comes from www.thinfilmtech.net. They have a product called GasPruf that is designed to line / remediate pipelines, petroleum tanks, etc. Its basically an epoxy. Here is a note from their spec sheet:GasPruf 130<sup>tm</sup>is a unique blend of liquid polymers and proprietary curing agents which is able to displace water or hydrocarbons such as gasoline or diesel fuel from wetted surfaces in order to make a permanent bond. The formulation is solvent-free to ensure safety and maximum technical performance. Kevlarä* fibers are incorporated for reinforcement and viscosity management to achieve high application rates -even under hydrocarbon liquids!

*

I also imagine that you could use things like JB Weld or Splash Zone on the outside of the tank, if you can access it and find the leak.

*

The seals for the new inspection ports were interesting. They were stainless steel, with a flat plate for the outside and two half-rings for the inside of the tank. He used them as a template to drill the holes outside the inspection port. He then threaded the bolts into the two half rings, sealing the threads with epoxy. He then made a gasket for the inside and outside of the tank, installed the two half rings inside with their gasket, then the outside plate with the gasket. The reason for the two half-rings was so that they could be passed through the hole. See: http://www.seabuilt.com/

*

The repair seems to be working perfectly. The leak is repaired and I have a new set of inspection ports if I ever need to get in there again.

Attachments

-

starboard fuel tank repair 6-05 006.jpg27.5 KB · Views: 544

starboard fuel tank repair 6-05 006.jpg27.5 KB · Views: 544 -

starboard fuel tank repair 6-05 008.jpg71.9 KB · Views: 647

starboard fuel tank repair 6-05 008.jpg71.9 KB · Views: 647 -

starboard fuel tank repair 6-05 009.jpg53.1 KB · Views: 515

starboard fuel tank repair 6-05 009.jpg53.1 KB · Views: 515 -

starboard fuel tank repair 6-05 010.jpg32.1 KB · Views: 543

starboard fuel tank repair 6-05 010.jpg32.1 KB · Views: 543 -

starboard fuel tank repair 6-05 022.jpg32.9 KB · Views: 682

starboard fuel tank repair 6-05 022.jpg32.9 KB · Views: 682 -

starboard fuel tank repair 6-05 027.jpg38.3 KB · Views: 528

starboard fuel tank repair 6-05 027.jpg38.3 KB · Views: 528 -

starboard fuel tank repair 6-05 030.jpg61.7 KB · Views: 548

starboard fuel tank repair 6-05 030.jpg61.7 KB · Views: 548 -

starboard fuel tank repair 6-05 032.jpg28.3 KB · Views: 575

starboard fuel tank repair 6-05 032.jpg28.3 KB · Views: 575 -

starboard fuel tank repair 6-05 035.jpg19.2 KB · Views: 638

starboard fuel tank repair 6-05 035.jpg19.2 KB · Views: 638 -

starboard fuel tank repair 6-05 037.jpg20.6 KB · Views: 601

starboard fuel tank repair 6-05 037.jpg20.6 KB · Views: 601