You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Did I Wait Too Long

- Thread starter Pgitug

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

MYTraveler

Guru

Maybe not if you have an on-engine secondary. Change both.

psneeld

Guru

I would use 10 micron if my engine secondary was 5 or less.

I have seen filters with great gobs of black slimy things hanging from them and the engine secondaries be whistle clesn.

That black filter looks normal to not bad at all.....

I have seen filters with great gobs of black slimy things hanging from them and the engine secondaries be whistle clesn.

That black filter looks normal to not bad at all.....

dhays

Guru

- Joined

- May 26, 2015

- Messages

- 9,045

- Location

- United States

- Vessel Name

- Kinship

- Vessel Make

- North Pacific 43

Do you have a vacuum gauge on your filters? If not, I would install one.

Are your primary filters set up so only one is selected at a time? Mine are and when I changed both the one that is used all the time was dirty and the other appeared completely clean.

What primary filtration does your Cummins call for? Mine are common rail so they have a 2 micron secondary filter and they call for 10 micron primary filters. You engine isn't a common rail system so is not as sensitive to fuel contamination. If Cummins calls for 30 micron primary I would do that.

Finally, how old are the filters that you pulled out?

Are your primary filters set up so only one is selected at a time? Mine are and when I changed both the one that is used all the time was dirty and the other appeared completely clean.

What primary filtration does your Cummins call for? Mine are common rail so they have a 2 micron secondary filter and they call for 10 micron primary filters. You engine isn't a common rail system so is not as sensitive to fuel contamination. If Cummins calls for 30 micron primary I would do that.

Finally, how old are the filters that you pulled out?

twistedtree

Guru

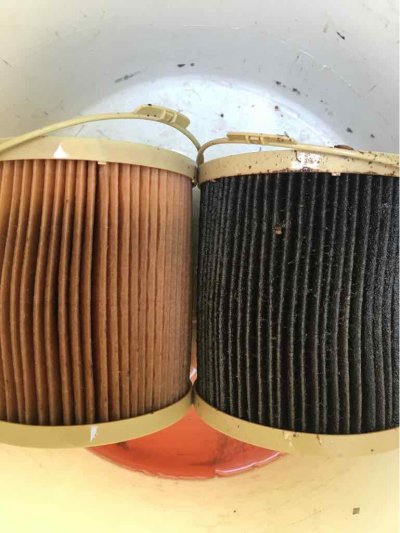

Are those two filters from a dual Racor setup? And have you been running on one but not the other, which would be normal? If so, I think they are normal.

Do you have a vacuum gauge with tell tale needle to show max vacuum? That will tell you if they are starting to plug up.

You should double check, but I think Cummins calls for 10 micron external to the engine.

Do you have a vacuum gauge with tell tale needle to show max vacuum? That will tell you if they are starting to plug up.

You should double check, but I think Cummins calls for 10 micron external to the engine.

pearlwindham

Veteran Member

I would not use 10... smallest doesn't mean best your injectors are rated for a certain size. Use what the factory specs out. If you need piece of mind polish

- Joined

- Oct 1, 2007

- Messages

- 7,331

- Location

- Texas

- Vessel Name

- Floatsome & Jetsome

- Vessel Make

- Meridian 411

I would not use 10... smallest doesn't mean best your injectors are rated for a certain size. Use what the factory specs out. If you need piece of mind polish

The factory specs are 10 microns for the Racor and then a Fleetguard FF5285(if memory serves me correctly)....which I have heard is 2 micron but I do not know for sure. And as far as polishing goes...a 6BTA pumps 4 times more fuel than it uses. So you are polishing the fuel....by default.

Mine look about like that when I change them!!

pearlwindham

Veteran Member

Than I retract. Go with the specs. the system is engineered as a whole you change one thing you start chasing Gremlings.

pearlwindham

Veteran Member

2 Microns sounds awfully small

dhays

Guru

- Joined

- May 26, 2015

- Messages

- 9,045

- Location

- United States

- Vessel Name

- Kinship

- Vessel Make

- North Pacific 43

2 Microns sounds awfully small

It is, which is kind of the point. My Cummins QSB calls for 2 micron secondary filters preceded by 10 Micron primary filters. I'm not sure what the earlier Cummins call for.

Ski in NC

Technical Guru

PGI- Looks pretty normal to me, except that you have probably been running on only one of the two filters. Change them both, but in the future switch from side to side occasionally. Let each do some of the job.

75/900 is a dual 900 series, 2040 elements. I run 10mic or 30mic depending on my mood.

75/900 is a dual 900 series, 2040 elements. I run 10mic or 30mic depending on my mood.

- Joined

- Oct 1, 2007

- Messages

- 7,331

- Location

- Texas

- Vessel Name

- Floatsome & Jetsome

- Vessel Make

- Meridian 411

2 Microns sounds awfully small

I will defer to the experts!!! And Ski is one of them. I did do some research on Boatdiesel et al. And it seems the consensus is as stated above. 10 primary(racor) followed by the on engine spec filter which, like I said, I think is 2 Microns..... That is not for me to question as it is the on engine spec filter for the engine. It might be 60000 micron. But I do believe it to be 2....the same formula for DLHays common rail QSB. I do believe we are over analyzing things here. I do not think that injector pumps/injectors/engines are failing at a rapid rate due to improper choices of fuel filters. If 30 microns "floats your boat", go for it. I honestly don't think there will be any negative repercussions. I would be a little more picky if I had a common rail engine.

And like Ski said, the OP likely has a dual set up where one filter was never used. Either run them in series or switch between the two(the favored option). But one was wasted and never used....at least that is the way it appears.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

"2 Microns sounds awfully small'

But a 2 micron filter rating is not absolute , it will pass some 20 micron particles too.

With an old diesel injection system todays filtration is fantastic , what ever you choose will be better than the eng mfg dreamed of .

With very high pressure electronic injection of a new diesel,multiple filtration seems to be required.

With a fairly clean fuel system I prefer the 2 micron as the primaries are not in the engine room and are very easy to monitor or change.

But a 2 micron filter rating is not absolute , it will pass some 20 micron particles too.

With an old diesel injection system todays filtration is fantastic , what ever you choose will be better than the eng mfg dreamed of .

With very high pressure electronic injection of a new diesel,multiple filtration seems to be required.

With a fairly clean fuel system I prefer the 2 micron as the primaries are not in the engine room and are very easy to monitor or change.

ranger58sb

Guru

The factory specs are 10 microns for the Racor and then a Fleetguard FF5285(if memory serves me correctly)....which I have heard is 2 micron but I do not know for sure.

Than I retract. Go with the specs. the system is engineered as a whole you change one thing you start chasing Gremlings.

My Cummins QSB calls for 2 micron secondary filters preceded by 10 Micron primary filters. I'm not sure what the earlier Cummins call for.

Don't know about the Bs, but our 6CTAs call for 30 micron primaries and 10 micron secondaries.

I'd have guessed 30/10 for mechanical 6BTAs (same generation as our 6CTAs) and 10/2 for the newer common-rail QSBs... but that's without benefit of the Cummins manual for those particular engines.

-Chris

Last edited:

- Joined

- Oct 1, 2007

- Messages

- 7,331

- Location

- Texas

- Vessel Name

- Floatsome & Jetsome

- Vessel Make

- Meridian 411

Don't know about the Bs, but our 6CTAs call for 30 micron primaries and 10 micron secondaries.

I'd have guessed 30/10 for mechanical 6BTAs (same generation as our 6CTAs) and 10/2 for the newer common-rail QSBs... but that's without benefit of the Cummins manual for those particular engines.

-Chris

I was just going with what I (think I) read on boatdiesel.

Marlinmike

Guru

Tony Athen the boatdiesel.com guru calls for step filtering, which just so happens to be the cummins spec as well. I've seen plenty of people out engineer themselves by stating they have a 10 primary and a 10 secondary and state my secondary always looks great.... Have to remember the tigher the filter also creates a load on the fuel pump as well, stay with manufactures spec and buy your fuel at a reputable place and everything will be alright.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

"remember the tigher the filter also creates a load on the fuel pump as well"

Many larger boat engines were big truck sourced , the fuel pump is metal gears , just like a lube oil pump.

Many larger boat engines were big truck sourced , the fuel pump is metal gears , just like a lube oil pump.

MYTraveler

Guru

Tony Athen the boatdiesel.com guru calls for step filtering, which just so happens to be the cummins spec as well. I've seen plenty of people out engineer themselves by stating they have a 10 primary and a 10 secondary and state my secondary always looks great.... Have to remember the tigher the filter also creates a load on the fuel pump as well, stay with manufactures spec and buy your fuel at a reputable place and everything will be alright.

Actually, I believe Tony recommends installing a large spin-off type of "mud" filter in front of the primary, changing the primary to the same rating as the secondary, and keeping the secondary with the expectation of never having to change it.

- Joined

- Oct 1, 2007

- Messages

- 7,331

- Location

- Texas

- Vessel Name

- Floatsome & Jetsome

- Vessel Make

- Meridian 411

Actually, I believe Tony recommends installing a large spin-off type of "mud" filter in front of the primary, changing the primary to the same rating as the secondary, and keeping the secondary with the expectation of never having to change it.

And he just so happens to sell such a set up! My only knock on it would be the inability to see water in the bowl. I speak from experience. I had a fuel cooler fail and fill the tanks with raw water. Had there not been a filter bowl, I would have been lost and likely trashed one or both engines.

Last edited:

- Joined

- Oct 1, 2007

- Messages

- 7,331

- Location

- Texas

- Vessel Name

- Floatsome & Jetsome

- Vessel Make

- Meridian 411

I would use a 10. What did you drain out of the bowl(s). That would also give some insight.

I think the bowl would be after the filter... So only liquid contaminants would make it there???....ie....water

Pgitug

Guru

I would use a 10. What did you drain out of the bowl(s). That would also give some insight.

I had a half cup of sludge in the bottom of the dirty filter bowl. This was expected. We purchased the boat last summer in upstate NY and brought her down to the west coast of Florida. During our passage south, traveling in the Chesapeake, we had 25 knot winds from the north with following seas. Our fuel tanks were less than half full, as I was waiting to fuel up at Top Rack Marina, south of Norfolk. So the tanks in our 2002 Tug got a good stir.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

bilge53

Senior Member

- Joined

- Oct 5, 2007

- Messages

- 423

- Location

- USA

- Vessel Name

- M/V Major Award

- Vessel Make

- Senator 35 w/single Lehman

Everything is working. I would figure out how to route some fuel through the "clean" filter though. Change filters, fill her up and go see the world. Don't imagine a problem when there most likely is nothing going on that you haven't identified.

the filter on the left is still basically new and could be used more. the one on the right looks like its due(not overdue) to be replaced. if you want to know for sure when its time to change them. get a vacuum gauge and adapter from racor.

the cat spec has a max fuel supply restriction of 9 in-hg. i would advise you to check with cummins for an exact number on that specific engine. as for micron size. most all diesels run at least a 2 filter arrangement primary(water separator) and secondary (typically engine mounted). for most all cat stuff we use a 2 micron secondary and a 30 or 10 micron primary. when when you get into common rail fuel systems fuel quality becomes very important and we typically see 3 fuel filters with a step down in micron for each filter.

so with all that said if your tanks on the dirty side i would run 10's till the tanks clean up. filters are a lot cheaper than an injection pump or injectors.

Racor RK 11-1669 | Fisheries Supply

the cat spec has a max fuel supply restriction of 9 in-hg. i would advise you to check with cummins for an exact number on that specific engine. as for micron size. most all diesels run at least a 2 filter arrangement primary(water separator) and secondary (typically engine mounted). for most all cat stuff we use a 2 micron secondary and a 30 or 10 micron primary. when when you get into common rail fuel systems fuel quality becomes very important and we typically see 3 fuel filters with a step down in micron for each filter.

so with all that said if your tanks on the dirty side i would run 10's till the tanks clean up. filters are a lot cheaper than an injection pump or injectors.

Racor RK 11-1669 | Fisheries Supply

dhays

Guru

- Joined

- May 26, 2015

- Messages

- 9,045

- Location

- United States

- Vessel Name

- Kinship

- Vessel Make

- North Pacific 43

Actually, I believe Tony recommends installing a large spin-off type of "mud" filter in front of the primary, changing the primary to the same rating as the secondary, and keeping the secondary with the expectation of never having to change it.

iirc, the recommendation from Seabar Marine is a step filtering. A mud filter as you mention, but then stepped down filtering. For example, Cummins calls for 10 micron primary and 2 micron secondary for my 5.9 QSB engine (common rail, high pressure system). Tony will often recommend a 30 micron "mud filter" to put before that system to make sure that the 10 micron filters don't get suddenly overloaded in the event of something that might cause a lot of debri or water in the fuel.

So far, like the OP, my tanks and fuel have never had a problem so while adding that additional filtering stage would be good idea, likely over kill for me in my particular situation.

dhays

Guru

- Joined

- May 26, 2015

- Messages

- 9,045

- Location

- United States

- Vessel Name

- Kinship

- Vessel Make

- North Pacific 43

the filter on the left is still basically new and could be used more. the one on the right looks like its due(not overdue) to be replaced. if you want to know for sure when its time to change them. get a vacuum gauge and adapter from racor.

My primary filters looked much like the OPs when I changed them. One dirty, and the other clean. If I recall, Racor says that the filter elements do age even if they are not dirty. I don't see anything wrong with running on one of the parallel filters for normal use. This means that your backup filter should be completely clean in the even you need to use it.

My thinking (such as it is) goes like this. In normal use, the filters should not get dirty enough to cause any fuel restriction over their useful life (for me a year). If something unusual happens, such as a load of bad fuel, rough weather that might kick up debri from the bottom of an old tank, etc... then your working filter could get clogged. In that situation, I want to be able to switch over to the standby filter and have it be able to filter and function for as long as possible. During this time I will be in the ER changing out the clogged filter.

Now, lets say that an operator is switching which is the working filter on alternate uses. Then, in theory, both filters would be getting dirty at the same rate. So if something bad happens with the fuel, both filters might not have much spare filtering capability left. ie both might clog quickly not giving me as much time to change the filter.

Does that make any sense at all? I figure that I am going to change both filters yearly anyway. If one of the dual filters performs that entire time great. I see no need to switch back and forth (other than to simply make sure both sides of the system are working well).

Edit: I just did a little looking to substantiate my idea that the filter manufacturers recommend filter replacements based on time. I didn't find anything easily, which seems to me an indication that maybe it isn't an issue? I did find a good article by Steve D'antonio. In the article he recommended that you simply use vacuum restriction as an indicator for when to change the filter. In that article he mentions that the filter manufacturers do recommend at least annual changing of filters, but he points out that they have a vested interest. He writes that in his experience, he has not seen a filter fail from being submerged in diesel fuel.

Link to the article. Look near the very end of the article for his comments on replacement schedules.

So, maybe my yearly replacement of filters is overly aggressive. I think I will still continue that practice. If nothing else, it forces me to really get up close and personal with that portion of the fuel system. While I do checks on it daily, I admit that they tend to be cursory.

Last edited:

My primary filters looked much like the OPs when I changed them. One dirty, and the other clean. If I recall, Racor says that the filter elements do age even if they are not dirty. I don't see anything wrong with running on one of the parallel filters for normal use. This means that your backup filter should be completely clean in the even you need to use it.

My thinking (such as it is) goes like this. In normal use, the filters should not get dirty enough to cause any fuel restriction over their useful life (for me a year). If something unusual happens, such as a load of bad fuel, rough weather that might kick up debri from the bottom of an old tank, etc... then your working filter could get clogged. In that situation, I want to be able to switch over to the standby filter and have it be able to filter and function for as long as possible. During this time I will be in the ER changing out the clogged filter.

Now, lets say that an operator is switching which is the working filter on alternate uses. Then, in theory, both filters would be getting dirty at the same rate. So if something bad happens with the fuel, both filters might not have much spare filtering capability left. ie both might clog quickly not giving me as much time to change the filter.

Does that make any sense at all? I figure that I am going to change both filters yearly anyway. If one of the dual filters performs that entire time great. I see no need to switch back and forth (other than to simply make sure both sides of the system are working well).

technically everything is aging.

whether it goes bad or not is something else.

racor filter stacks can come with or without change over valve. i always prefer the ones with the valve. and its no problem to run with one as a secondary as long as your not creating an excessive amount of restriction. in fact it have seen may customers(hospitals/data centers/ect) running a racor triple stack(2020) with one as backup. we did not see any noticeable increase in restriction till we cut it down to just one filter. the engine transfer pump moves 5.5 gpm at rated speed so the flow requirements are significantly higher than anyone here is likely to see.

ps: overkill is underrated.

Similar threads

- Replies

- 63

- Views

- 10K

- Replies

- 15

- Views

- 3K

- Replies

- 26

- Views

- 3K