JDCAVE

Guru

- Joined

- Apr 3, 2011

- Messages

- 2,906

- Location

- Canada

- Vessel Name

- Phoenix Hunter

- Vessel Make

- Kadey Krogen 42 (1985)

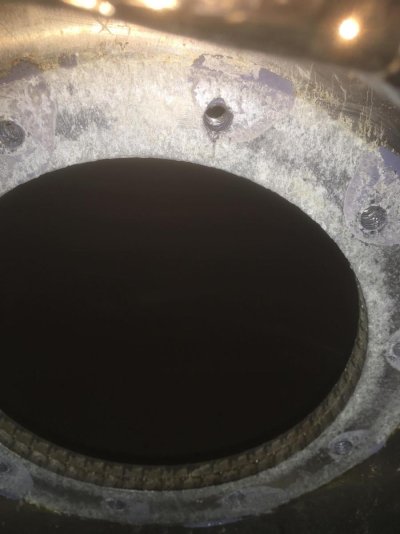

Prior to refuelling this year, I am thinking about transferring my fuel to a single tank and go through the process of opening the inspection ports and cleaning them out. 4 tanks, 2 ports each. I have an ESI fuel polishing system, but it doesn't address the sludge on the bottom of tanks. Any advice on how to proceed? I understand that the absorbent oil pads shed fibres and these should not be used. I'm expecting it to be a messy job. Thoughts? Experiences?

Jim

Jim