FLetcher What says your engine builder, not a marine mechanic with a Volvo hat but the builder?

They are in a different country, and if I was able to contact them, my guess is they would echo the predominant sentiment of the responses so far "these systems are designed to handle build up over time, they have a safety factor in the tube bundles so don't worry about it Mr. boat owner you are fine, and boil the coolers as per the manual"

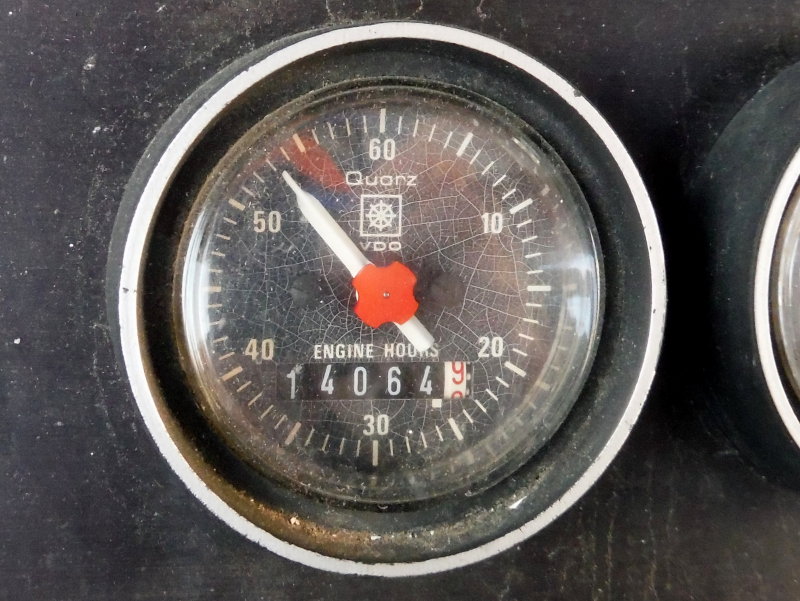

In general I agree with this, because a good raw water bundle is heavy duty, and could be shot with a machine gun and still work, but there are a lot of different factors for each of us depending on the waters we boat in, are we 365 with no winterizing, etc. As noted, after 2.5 years, of running the boat almost every week, I am seeing some mild signs of build up so I want to be proactive.

I personally think the chemical cleaning is not more common because most service centers don't want to hassle with it. IE, the fluid has to circ for a few hours, so there is downtime unless the mechanic has other things to do, and then there is the disposal of the spent solution. Technically, it is harmless and it can be poured in to the ocean but a company may not want to take that chance in the event they are caught pouring it in, and someone thinks it is a haz material..but its not.

So unless its a DIY deal, and in which case you need to configure a tank, pump, find a way to pump it, etc., it wont happen. I am still unable to work on my engines myself, so I need to have certified mech's do it, while the warranty is in place.

I therefore believe weak acid solutions like RL or BB are beneficial, and I will be doing it soon, and probably very few years thereafter. You can put your hand in the stuff when its recirculating, and it warm the skin so its not a strong solution.

I am still somewhat skeptical of the fresh water flush for reasons noted. I think this has the potential to create more headaches than its worth.