Tacomasailor

Veteran Member

You guys were so helpful with the weak bolts I thought I'd try for more advice.

I've attached two photos

The material on the heat exchanger front around the cap that holds the coolant bundle in place is badly corroded/eroded for about 40% - 50% of the circumference. The O-ring that seals the cap onto the HE face was protruding for about 1/2" of the circumference.

A local welder, with an excellent reputation in the local boating community, says he can rebuild that material and it will be as good as new (after I remove the exchanger bundle).

What would have caused that erosion of the material. There were no leaks at all, I kept a close eye on the cap because it is right above the 135-amp alternator and a leak or drip would be a disaster.

Can the material be re-deposited by a good welder?

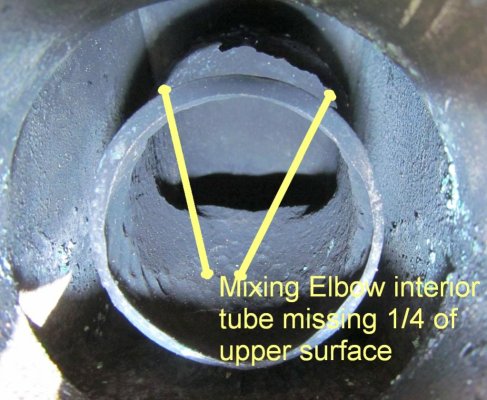

The Yanmar Type U mixing elbow has about 1/4 of the upper surface of the inner tube missing. That tube carries the exhaust gas stream to the rear of the elbow where it should join with the raw water flow.

The missing material is downstream from where the exhaust gas stream makes a 90 degree bend to head down to the water lift muffler.

Does that hole cause any problems?

I've attached two photos

The material on the heat exchanger front around the cap that holds the coolant bundle in place is badly corroded/eroded for about 40% - 50% of the circumference. The O-ring that seals the cap onto the HE face was protruding for about 1/2" of the circumference.

A local welder, with an excellent reputation in the local boating community, says he can rebuild that material and it will be as good as new (after I remove the exchanger bundle).

What would have caused that erosion of the material. There were no leaks at all, I kept a close eye on the cap because it is right above the 135-amp alternator and a leak or drip would be a disaster.

Can the material be re-deposited by a good welder?

The Yanmar Type U mixing elbow has about 1/4 of the upper surface of the inner tube missing. That tube carries the exhaust gas stream to the rear of the elbow where it should join with the raw water flow.

The missing material is downstream from where the exhaust gas stream makes a 90 degree bend to head down to the water lift muffler.

Does that hole cause any problems?