psneeld

Guru

Temporarily anything will work, heck use hot water rated PVC.

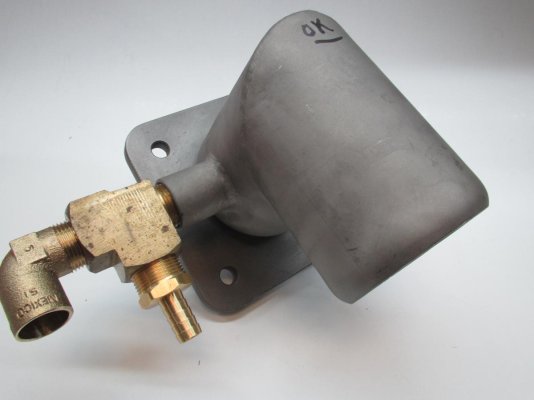

The pieces and parts that are pipe or fittings for the salt water runs on my Lehman are eithe brass or copper and are decades old.

Yeah, a lot of chest beating but realiry wins as many boat components are copper where saltwater runs...like air conditioning components/coils.

Get it running today or tomorrow...worry about failures 20 years from now next week....if you choose to.

The pieces and parts that are pipe or fittings for the salt water runs on my Lehman are eithe brass or copper and are decades old.

Yeah, a lot of chest beating but realiry wins as many boat components are copper where saltwater runs...like air conditioning components/coils.

Get it running today or tomorrow...worry about failures 20 years from now next week....if you choose to.