phillippeterson

Senior Member

- Joined

- Nov 11, 2020

- Messages

- 384

Would you mind giving pros and cons of engine cooling by seawater vs engine cooling by radiator.

I think this is referring to aftercoolers. Seawater aftercoolers aren't as streaks durable as one in the coolant loop and need more maintenance. But they can get the air colder, enabling higher performance.

Perhaps the OP will clarify. I`m thinking its about on engine heat exchanger cooling vs more remote keel cooling. Most of us understand heat exchanger, the most helpful responses could be from someone with keel cooling experience.

The main con of a marine engine cooled by an air radiator is there aren't any.

Actually, I guess don't really know what I'm asking. I was looking at Deere marine diesels and some are A and some are S - the aforementioned air to coolant and air to seawater after coolers. These options are mentioned under the heading of aspiration. Revisiting the Deere page, I now surmise they are talking about the air charge cooling after the turbocharger and not the engine cooling.

Got it. My Cummins 210s don`t have/need aftercooling,unlike higher output versions of the 5.9 block. Less servicing/less to go wrong.Actually, I guess don't really know what I'm asking. I was looking at Deere marine diesels.... Revisiting the Deere page, I now surmise they are talking about the air charge cooling after the turbocharger and not the engine cooling.

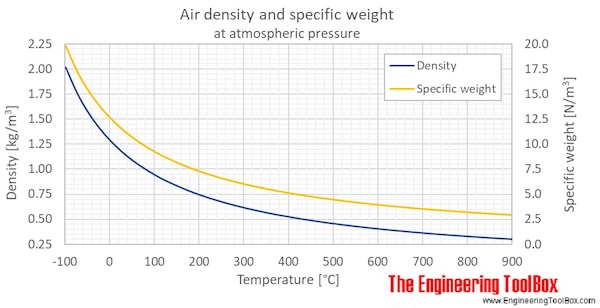

Here's a rough guess: assume coolant is 90C and seawater is 20C, density of air goes from 1.2 to just under 1.0 (kg/m^3), so you get about 16% more oxygen for the fuel to react with in a given cylinder volume, which will translate to 16% more torque or HP if there aren't other constraints.

So it's the difference between a 500hp engine and a 580hp engine. Material for a planing boat I'd say, given no weight penalty.

But again, that is the coolant temp exiting the hot engine. Certainly any engineer worthy of his degree would use the coolant after it has been through the seawater heat exchanger and is close to seawater temperature. Only the coolant exiting the block is at 90 °C, the coolant entering the block should be only a little elevated above seawater. If it is also 90° then your engine is about to overheat.