Got a pair of 6BT5.9M 1988 vintage @ 3200 hrs. ea.

Since getting the boat in 2014, port engine started having intermittent starting problems. At beginning of this season, we had the injectors overhauled, filled the tanks and the thing was fine all summer ( 100 hrs. ) . Prior to haul out recently and after oil changes, the port engine would not start again ! Had to crank quite a bit ( there was no sign of it trying to catch .. just dead crank ! ) and on the 3 rd. / 4 th. 30 sec. crank cycle, the thing would start. Once starts, it runs fine .... although it did quit " once " right after start at idle rpm.

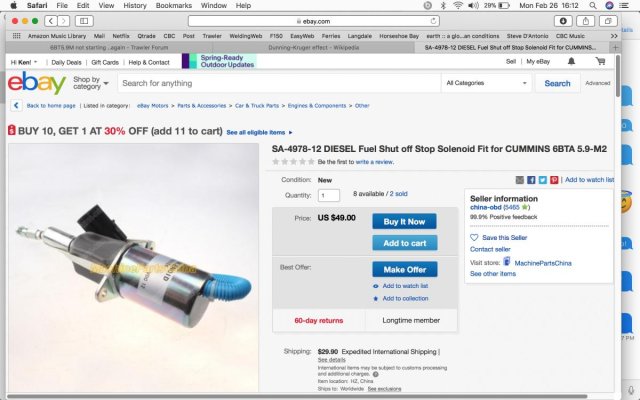

Marina Tech thinks it could be the lift pump as a start ..... then maybe the fuel shut off & sol. ... ? and so on .... he's not sure at this time.

Of note: The fuel is @ 1/2 tanks, ( tanks are plumbed together ) filters are very clean too and are full of fuel.

As a side question and when priming by hand at the lift pump: should the ignition switch be in the ON position ???

Any comments, thoughts would be appreciated before we have the Tech dive into this this thing @ 125.00 / hr.

Tx in advance .... F

Since getting the boat in 2014, port engine started having intermittent starting problems. At beginning of this season, we had the injectors overhauled, filled the tanks and the thing was fine all summer ( 100 hrs. ) . Prior to haul out recently and after oil changes, the port engine would not start again ! Had to crank quite a bit ( there was no sign of it trying to catch .. just dead crank ! ) and on the 3 rd. / 4 th. 30 sec. crank cycle, the thing would start. Once starts, it runs fine .... although it did quit " once " right after start at idle rpm.

Marina Tech thinks it could be the lift pump as a start ..... then maybe the fuel shut off & sol. ... ? and so on .... he's not sure at this time.

Of note: The fuel is @ 1/2 tanks, ( tanks are plumbed together ) filters are very clean too and are full of fuel.

As a side question and when priming by hand at the lift pump: should the ignition switch be in the ON position ???

Any comments, thoughts would be appreciated before we have the Tech dive into this this thing @ 125.00 / hr.

Tx in advance .... F