The Brockerts

Senior Member

- Joined

- Oct 17, 2014

- Messages

- 246

- Location

- USA

- Vessel Name

- Moonstruck

- Vessel Make

- 1990 Californian/Carver 48 MY

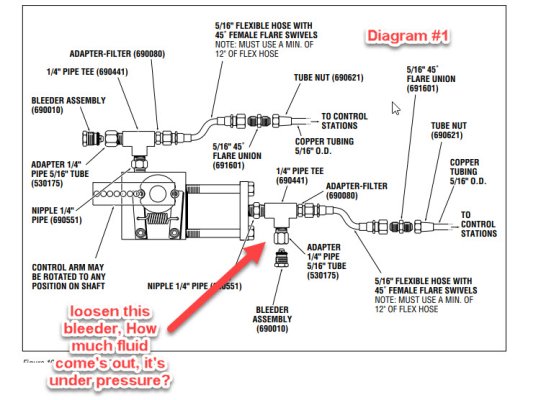

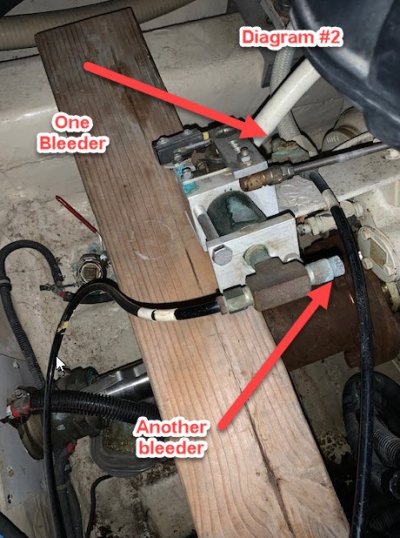

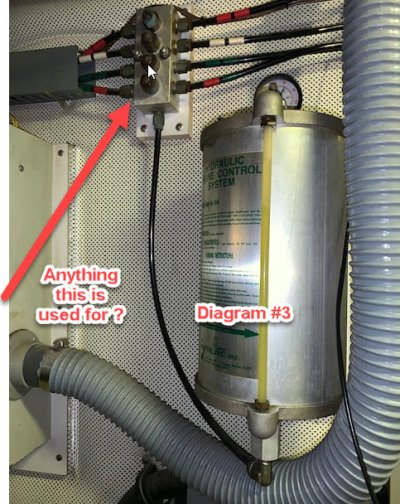

It’s time for a hynautic transmission bleed, I think. All controls (throttles and starboard transmission) work well. The PORT transmission is very soft, doesn’t stay in place and as I was played with it yesterday would not go into reverse. I disconnect the hynautice slave from the transmission lever. Then I was able to work the transmission lever just fine. Felt solid clicked into place, springs and mechanicals all worked as I expected. I’ve never bled any system like this so the closest I can come to is bleeding brakes on a car. Seems like the same principals would apply. Dug through the TF with search’s and didn’t find much on the topic. The web and seastar provided a manual with bleed process described. From that doc and diagrams http://www.seastarsolutions.com/wp-content/uploads/2011/06/182042C.pdf I’m building my plan. Several questions come to mind. Step 2 page 15, talks about opening the bleeder value 1 turn. Now it seems like I’ll have fluid spraying out given there is about 100psi sitting on the other end that. Getting that cap off and getting a 5/16 tube into it seems like a mess is going to happen. Seem like there is a good possibility to spray this fluid everywhere. Do I open both bleeder values at the same time, or one at a time? I need to be moving the handles for this process to. I’ll have to track down the tape nomenclature. Seems to be one tape line return? 2 tape line the send? Also, I’ve attached a picture of a manifold. Anything this is used for in this process? Can I just bleed the one line without effecting the other lines? Any words of wisdom?

The Brockerts

The Brockerts