wkearney99

Guru

- Joined

- Feb 17, 2018

- Messages

- 2,164

- Location

- USA

- Vessel Name

- Solstice

- Vessel Make

- Grand Banks 47 Eastbay FB

So, why does your back hurt this morning?

Hand-over-hand retrieval of chain and anchor gives you quite the work out. Thankfully at 9' deep it was a shallow anchorage so my usual 5:1 scope wasn't too much. But, oy, it was a chore. Upside though, overnight anchoring on the Corsica River was pleasant.

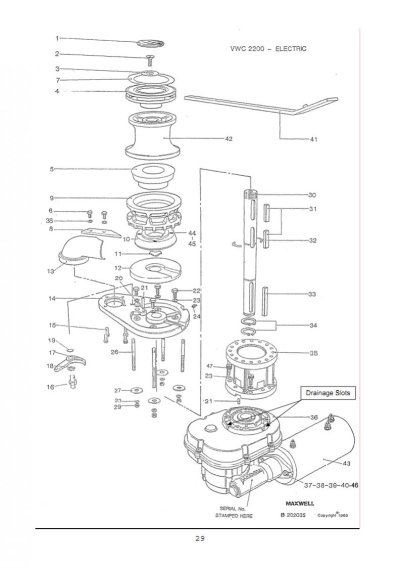

No idea what's going on yet, as I didn't have an opportunity to tear it down this weekend. The symptom is it'll turn the capstan drum but not the chainwheel. It's an electric Maxwell 2200 VWC. Tightening the clutch nut did nothing to get the chainwheel to grab. The drum is above the clutch for the chainwheel. The drum #42 has a key #31 engaging in into the shaft, so the clutch doesn't affect it. The upper (outer) clutch cone spins free on the shaft. It's the pressure of the clutch nut pushing down that engages enough pressure on the clutch cones to make the chainwheel turn.

Attached is a picture from disassembling it last season to service it, and the parts diagram. In the picture you can just make out the top of the key sticking out above the lower (inner) cone.

I'm thinking #32, the key for the lower clutch cone must have sheared?

Anyone else run into a similar problem with a Maxwell windlass?

Hand-over-hand retrieval of chain and anchor gives you quite the work out. Thankfully at 9' deep it was a shallow anchorage so my usual 5:1 scope wasn't too much. But, oy, it was a chore. Upside though, overnight anchoring on the Corsica River was pleasant.

No idea what's going on yet, as I didn't have an opportunity to tear it down this weekend. The symptom is it'll turn the capstan drum but not the chainwheel. It's an electric Maxwell 2200 VWC. Tightening the clutch nut did nothing to get the chainwheel to grab. The drum is above the clutch for the chainwheel. The drum #42 has a key #31 engaging in into the shaft, so the clutch doesn't affect it. The upper (outer) clutch cone spins free on the shaft. It's the pressure of the clutch nut pushing down that engages enough pressure on the clutch cones to make the chainwheel turn.

Attached is a picture from disassembling it last season to service it, and the parts diagram. In the picture you can just make out the top of the key sticking out above the lower (inner) cone.

I'm thinking #32, the key for the lower clutch cone must have sheared?

Anyone else run into a similar problem with a Maxwell windlass?