The Brockerts

Senior Member

- Joined

- Oct 17, 2014

- Messages

- 246

- Location

- USA

- Vessel Name

- Moonstruck

- Vessel Make

- 1990 Californian/Carver 48 MY

In my new to me 1990 Californian/Carver MY, I've completed a rebuild of the the waste systems, the bottom, the kitchen and now I'm moving to the electrical systems. Need to document how it's configured first, and I'm looking for idea's on the best way to do that. Very few wire's are labeled on both ends.

Do I just start turning things off and go looking for what doesn't work?, Do I disconnect wire's and run continuity tests on wires?, Combination of both methods?

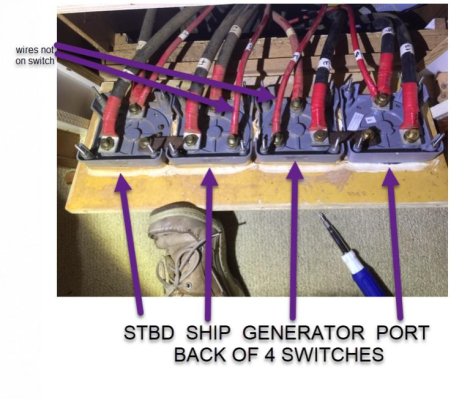

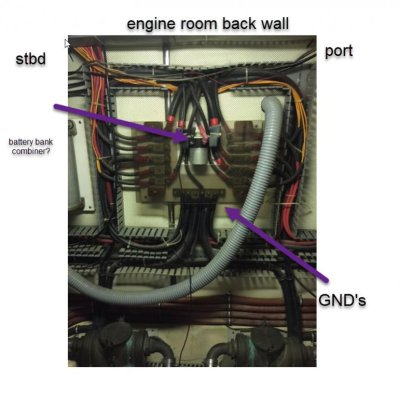

I've attached a few pictures. I have 2 battery banks. Each bank is 2 -8D connected in parallel and it looks like one for port engine and one for starboard engine. I've got 4 simple on/off switches. Look like the generator is connected to the port battery bank and the house is connected to the STBD battery bank. So the house only uses on battery bank?

It looks like wires run from the battery + to the 4 switches first and then to the panel in the engine room. Seems reasonable.

However there are 2 wires that do not go thru the switches? I'm guessing something like bilge pumps maybe ?

I'm looking for some words of wisdom from this group before I dig into this project.

The Brockerts

Do I just start turning things off and go looking for what doesn't work?, Do I disconnect wire's and run continuity tests on wires?, Combination of both methods?

I've attached a few pictures. I have 2 battery banks. Each bank is 2 -8D connected in parallel and it looks like one for port engine and one for starboard engine. I've got 4 simple on/off switches. Look like the generator is connected to the port battery bank and the house is connected to the STBD battery bank. So the house only uses on battery bank?

It looks like wires run from the battery + to the 4 switches first and then to the panel in the engine room. Seems reasonable.

However there are 2 wires that do not go thru the switches? I'm guessing something like bilge pumps maybe ?

I'm looking for some words of wisdom from this group before I dig into this project.

The Brockerts