TheLake

Veteran Member

- Joined

- Oct 16, 2021

- Messages

- 51

- Vessel Name

- The Lake

- Vessel Make

- 42' CHB Tricabin

For a variety of reasons I have decided to take the plunge and rewire my 80's vintage CHB 42' Trawler.

The project has started and I have removed all my batteries and shore power and I am actively stripping out all the old wiring. I know it's going to be a big job, but I am looking forward to it.

As I pull out the wiring, a number of things have come to light that make me think that there are some other "side projects" that I should do at the same time:

I am building out a new electrical system in Visio and then will get it validated by a Marine Electrician.

My initial question to the group is: is there a market for the used electronics that I am taking off? I have an old Freedom 20 inverter/charger, my old DC and AC panels, etc. that I am replacing. Should I be trying to sell these or just take them to recycle?

Some initial pictures are attached.

Cheers,

Chris

The project has started and I have removed all my batteries and shore power and I am actively stripping out all the old wiring. I know it's going to be a big job, but I am looking forward to it.

As I pull out the wiring, a number of things have come to light that make me think that there are some other "side projects" that I should do at the same time:

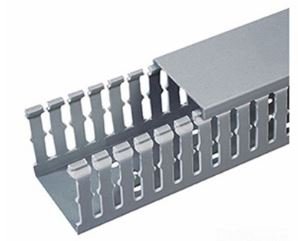

- Soundproofing the engine room - as I look to get access to the old wires (alot of wires abondoned) I have taken the roof off the engine room, including the white "holey" panels that the manufacturer put on. Since I have removed the plywood from the engine room roof, I am going to put something newer in for sound insulation

- Hydraulics for steering - the last owner told me the hydraulics were leaking and constantly needed to be topped up. Looking at the old copper pipes with many connections, I can see why. I am going to rerun these with flexible hydraulic tubing and get the pumps and pistons rebuilt

- Plumbing - lots of old copper that needs to be removed to get access to the ceiling. So going to replace with PEX pipe

- Spongy flybridge floor - since I am doing the work I have decided to remove the headliner and repair a bit of sponginess in the flybridge floor

I am building out a new electrical system in Visio and then will get it validated by a Marine Electrician.

My initial question to the group is: is there a market for the used electronics that I am taking off? I have an old Freedom 20 inverter/charger, my old DC and AC panels, etc. that I am replacing. Should I be trying to sell these or just take them to recycle?

Some initial pictures are attached.

Cheers,

Chris

Last edited: