Lou_tribal

Guru

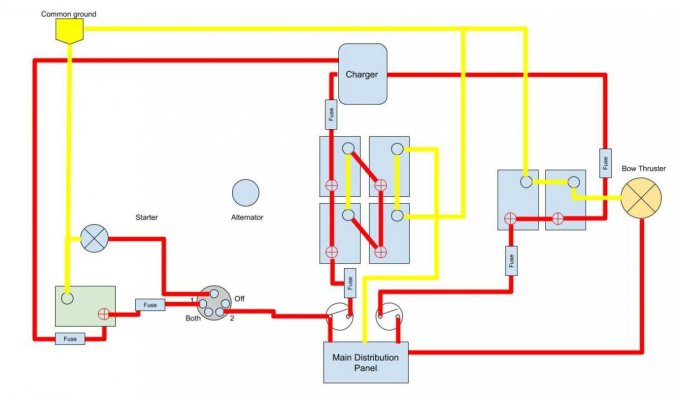

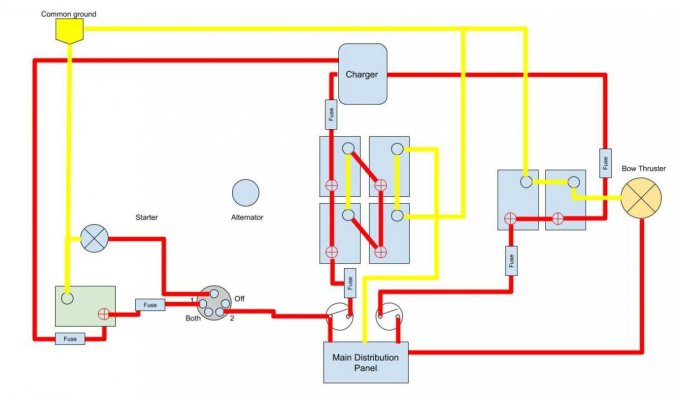

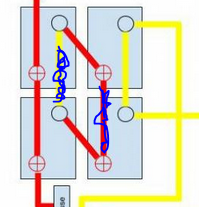

Below is the setup I plan for my new gc2 batteries bank and new charger.

Any comment, input, suggestion will be welcome.

The plan is to keep my old g31 as a thruster dedicated bank.

I am still questioning myself about alternator setup, using either a charge splitter (like ProIsoCharge or equivalent) or 2 VSR to link the 3 bank between them. What do you think?

(Already posted this on my renovation thread but think it would fit here as electrical subject)

L

Any comment, input, suggestion will be welcome.

The plan is to keep my old g31 as a thruster dedicated bank.

I am still questioning myself about alternator setup, using either a charge splitter (like ProIsoCharge or equivalent) or 2 VSR to link the 3 bank between them. What do you think?

(Already posted this on my renovation thread but think it would fit here as electrical subject)

L

![url]](/proxy.php?image=http%3A%2F%2F%5Burl%5Dhttps%3A%2F%2Fwww.marineoutfitters.ca%2Fimages%2Fproducts%2FBlue%2520Sea%25207181.jpg%5B%2Furl%5D&hash=48d03243f76fd9c9a5e409a88f15ecf0)