JDCAVE

Guru

- Joined

- Apr 3, 2011

- Messages

- 2,908

- Location

- Canada

- Vessel Name

- Phoenix Hunter

- Vessel Make

- Kadey Krogen 42 (1985)

I made the mistake of mentioning to my surveyor that I intended to upgrade to the “Smart Plug” for my shore power. He said “That’s a great idea and while your at it replace the service to the panel as well!” Problem is he made it a requirement that this be done within the next 4 months of survey. Lesson learned: never, EVER, offer up low hanging fruit to your surveyor!

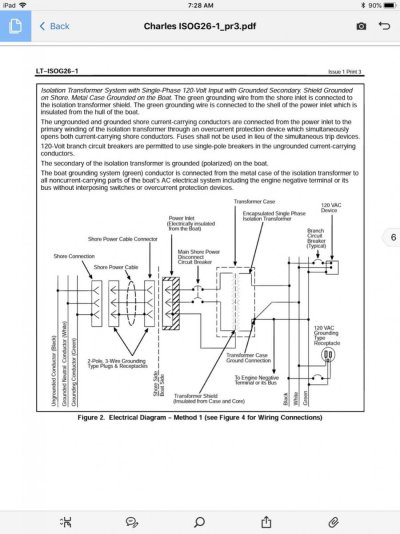

So why does AYBC call for a breaker within XX inches of the shore power inlet, when you have a breaker on the shore power pedestal and a breaker on the panel? Have any KK42 owners done this upgrade and if so, where did you locate the breaker? The shoreside power inlet is easily accessed inside the vessel by the access door behind washer/dryer units.

Jim

So why does AYBC call for a breaker within XX inches of the shore power inlet, when you have a breaker on the shore power pedestal and a breaker on the panel? Have any KK42 owners done this upgrade and if so, where did you locate the breaker? The shoreside power inlet is easily accessed inside the vessel by the access door behind washer/dryer units.

Jim