jhance

Senior Member

I am adding some electrical and want to improve a few things on the boat. Some basic/newbie questions below.

1. Any issues running multiple terminal or junction blocks in one circuit? This if I want to branch off different sets of lights in different directions.

2. Are junction blocks THE preferred method for making a junction between three or more wires?

3. How would you bring two positive wires together and then run a single from there to power source?

4. Good idea to fuse an LED lighting circuit even if connected to circuit breaker?

5. Lighting circuit with multiple runs should go to a fuse or terminal block and then one thicker wire to breaker for one connection at breaker?

6. Terminal block the best way to join two wires of different gauge?

This of course using the proper crimped terminals with proper size wire.

Not used to DC wiring. In AC it's all done with wire nuts and junction boxes!

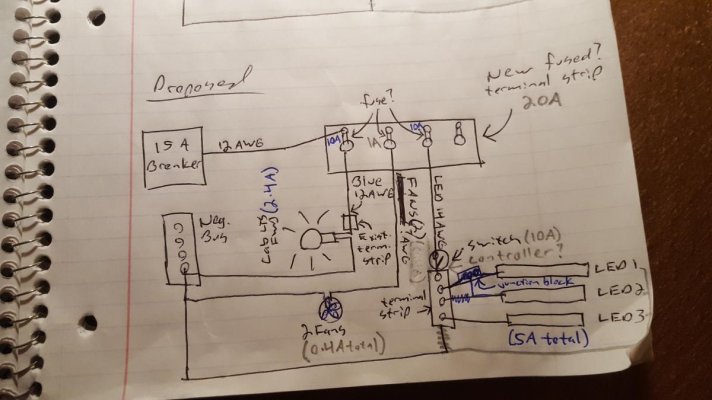

My very crude circuit attached. Most of that is existing wiring. Adding the LED sections and removing multiple connections at the breaker. Input welcomed if there is a better way.

Thanks in advance.

Jamey

1. Any issues running multiple terminal or junction blocks in one circuit? This if I want to branch off different sets of lights in different directions.

2. Are junction blocks THE preferred method for making a junction between three or more wires?

3. How would you bring two positive wires together and then run a single from there to power source?

4. Good idea to fuse an LED lighting circuit even if connected to circuit breaker?

5. Lighting circuit with multiple runs should go to a fuse or terminal block and then one thicker wire to breaker for one connection at breaker?

6. Terminal block the best way to join two wires of different gauge?

This of course using the proper crimped terminals with proper size wire.

Not used to DC wiring. In AC it's all done with wire nuts and junction boxes!

My very crude circuit attached. Most of that is existing wiring. Adding the LED sections and removing multiple connections at the breaker. Input welcomed if there is a better way.

Thanks in advance.

Jamey

Attachments

Last edited: