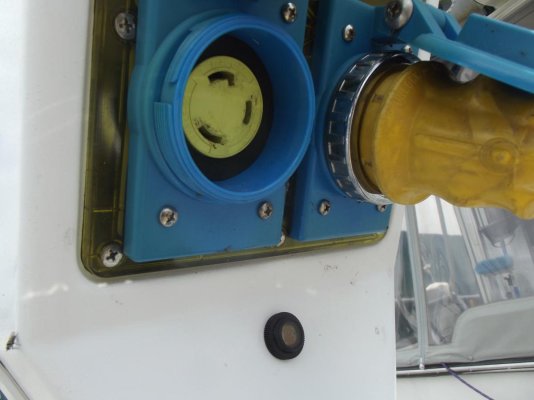

Statistically speaking, most boat fires are the result of shore power faults. One observation from the photo, the back of those inlets are supposed to be covered/insulated, you should do that on the replacement, even if it's a Smart Plug, their inlets lack full insulation without an enclosure. If you can see a energized screw, it should be covered.

Steve as designed the hull inlet connectors produced today from Hubble, Marinco and Smart plug do not have any exposed electrical connections where someone might accidentally contact it and get a shock. I suppose you could stick your fingers into the recessed set screws if you tried though.

What I see in that picture though is that the boat wiring is not supported and the weight of the hull cable wiring is hanging on the wire connections of the hull inlet. The wire should be secured and supported independently of the hull inlet.

My standard for AC connections is if I can see it, or touch it, even with the tip of my finger, I consider it un-insulated. Part of my concern is water dripping on the connection, if it's exposed that becomes a possibility. I believe you are correct, late model Marinco and Hubbell inlet backs are fully enclosed.

This photo, of a Smart Plug back, taken on a recent inspection, illustrates the point regarding exposure. I believe these should be enclosed/covered.

As far as wire support goes, you are correct, that too is an issue. As far as ABYC standards are concerned, if you can pull on a wire and that force is transmitted to the connection at an enclosure (a common issue on battery chargers, inverters, transformers), it's not compliant, strain relief should be present. The same holds true for a shore inlet terminals. The wires themselves should be supported a minimum of every 18".

ABYC E-11.14.4.1.2 All conductors shall be supported and/or clamped to relieve strain on connections.

11.14.4.1.3 All AC cables from the shore power inlet to the main shore power breaker shall be in conduit or supported according to E-11.14.4.1.9.2 or E-11.14.4.1.9.3.

11.14.4.1.9 Conductors shall be supported throughout their length or shall be secured at least every 18 inches (455 mm) by one of the following methods:

11.14.4.1.9.1 By means of nonmetallic clamps sized to hold the conductors firmly in place. Nonmetallic straps or clamps shall not be used over engine(s), moving shafts, other machinery, or passageways, if failure would result in a hazardous condition. The material shall be resistant to oil, gasoline, and water and shall not break or crack within a temperature range of -40°F (-40°C) to 185°F (85°C);

11.14.4.1.9.2 By means of metal straps or clamps with smooth, rounded edges to hold the conductors firmly in place without damage to the conductors or insulation. That section of the conductor or cable directly under the strap or clamp shall be protected by means of loom, tape, or other suitable wrapping to prevent injury to the conductor;

11.14.4.1.9.3 By means of metal clamps lined with an insulating material resistant to the effects of oil, gasoline, and water.

50 amp.

50 amp.