Redhook98

Senior Member

- Joined

- Jun 26, 2019

- Messages

- 365

- Location

- US

- Vessel Name

- Tatoosh

- Vessel Make

- 1979 49ft Marine Trader RPH

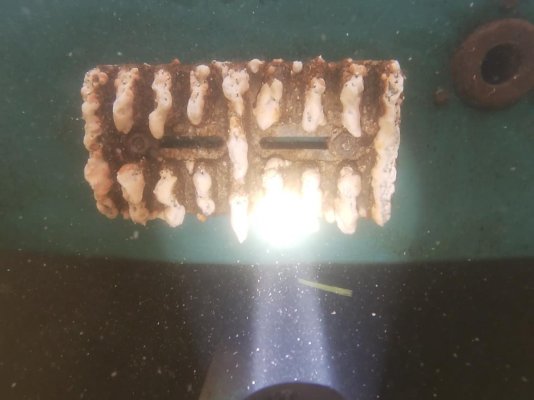

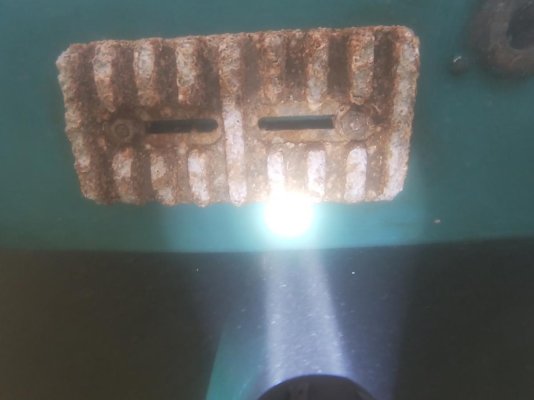

I had my MT 49 RPH out for new cutlass bearings, paint and a few other maintenance issues recently. I had the yard put on new aluminum anodes on the shafts, rudders and struts. In the two week period in the water before it was yanked out again, there was noticeable wear on the anodes. I am on the middle Potomac so it is fresh/brackish water situations.

I have no bonding of any kind currently in the boat. It was removed by a PO. All external metals were protected only by the zincs attached to them. No signs of any corrosion issues right now. I installed two separate galvanic isolators (one on each power input). The PO had installed one incorrectly and the other line didn't have one at all.

My idea is this. I had them drill the transom and install a Divers Dream aluminum anode. I am planning on connecting the shafts (via a shaft brush), the struts and rudders to the transom anode. There is a 50-ohm separation between the trannys and the shafts, so those are not in the equation. Only the below water line exposed metal will be connected to the new bonding system. This is only for corrosion control. Not concerned about normal thru-hulls as they are just isolated chunks of metal and are not feeding the issue.

Is there any reason this would not work and extend the life of my anodes?

With just the aluminum anodes right now, using the proper test anode (silver-silver chloride), I am getting readings of -.6 to -.700 volts of activity at each shaft, rudder and strut. These should be around -1.1v. Theoretically, the addition of the large anode to the equation should get me there.

I have no bonding of any kind currently in the boat. It was removed by a PO. All external metals were protected only by the zincs attached to them. No signs of any corrosion issues right now. I installed two separate galvanic isolators (one on each power input). The PO had installed one incorrectly and the other line didn't have one at all.

My idea is this. I had them drill the transom and install a Divers Dream aluminum anode. I am planning on connecting the shafts (via a shaft brush), the struts and rudders to the transom anode. There is a 50-ohm separation between the trannys and the shafts, so those are not in the equation. Only the below water line exposed metal will be connected to the new bonding system. This is only for corrosion control. Not concerned about normal thru-hulls as they are just isolated chunks of metal and are not feeding the issue.

Is there any reason this would not work and extend the life of my anodes?

With just the aluminum anodes right now, using the proper test anode (silver-silver chloride), I am getting readings of -.6 to -.700 volts of activity at each shaft, rudder and strut. These should be around -1.1v. Theoretically, the addition of the large anode to the equation should get me there.