HopCar

Guru

- Joined

- Aug 20, 2011

- Messages

- 5,308

- Vessel Name

- Possum

- Vessel Make

- Ellis 28

Most of us have had a snap pull out of fiberglass leaving the hole too big to just screw it back in. Forget epoxy, this is far easier.

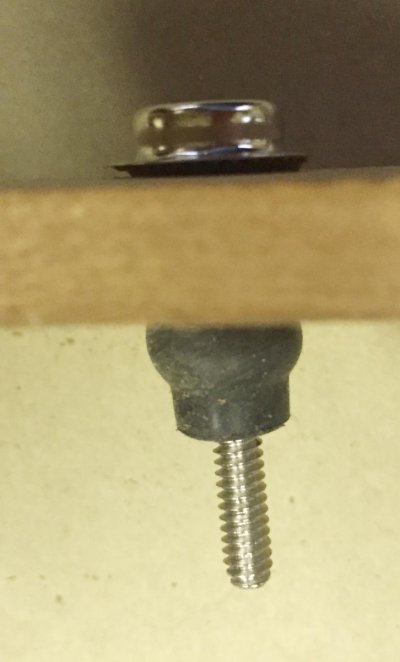

You need a replacement snap without a screw, a #6 rubber expansion nut that is long enough to go through the fiberglass and a #6 flat head machine screw long enough to go through the expansion nut.

Drill the hole out to the OD of the expansion nut. In this case it was 5/16”. Shove the expansion nut through the fiberglass. Put the snap on the machine screw and screw the machine screw into the expansion nut. You’re done.

This is probably stronger than the original installation and I’m pretty sure it’s waterproof.

You need a replacement snap without a screw, a #6 rubber expansion nut that is long enough to go through the fiberglass and a #6 flat head machine screw long enough to go through the expansion nut.

Drill the hole out to the OD of the expansion nut. In this case it was 5/16”. Shove the expansion nut through the fiberglass. Put the snap on the machine screw and screw the machine screw into the expansion nut. You’re done.

This is probably stronger than the original installation and I’m pretty sure it’s waterproof.