You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Salon Table build

- Thread starter fryedaze

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

The problem is I got a lot of bubbles when doing the epoxy. ...

Same thing happened with the varnish in the same environmental conditions.

Here is one idea: I had this problem twenty years ago when doing a bunch of trim for my sailboat. I had removed it so was in a "varnish room." Every darned coat, when I came back the next day, looked like it had "dust" in it. The room was so clean! I'd sand it down, do another coat, come back the next morning..... MORE. I was at my wit's end. There was not so much Internet at that time (how did we find anything out? I can't remember).

Finally I read somewhere that it might be bubbles, which would be caused if the temperature of the wood was rising as the varnish was drying. Bingo! I was varnishing at "room temperature," but then since it was a coolish shop I would turn a space heater on for the night. Hence my wood was actually warming as the varnish dried.

Next coat (15th, IIRC

Now I make sure to have wood at the "warmest" point as I apply varnish (or epoxy if I want it clear) and have it on a slight cooling cycle as it cures. No more bubbles. Now my dust (when it exists) is actually dust!

fryedaze

Guru

- Joined

- Sep 4, 2011

- Messages

- 1,722

- Location

- USA

- Vessel Name

- Fryedaze

- Vessel Make

- MC 42 (Overseas Co) Monk 42

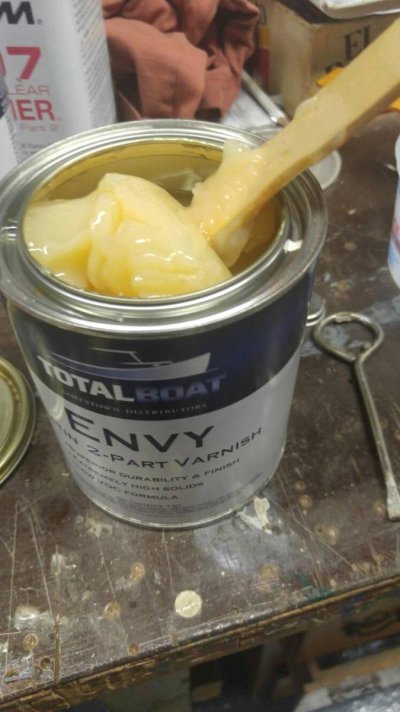

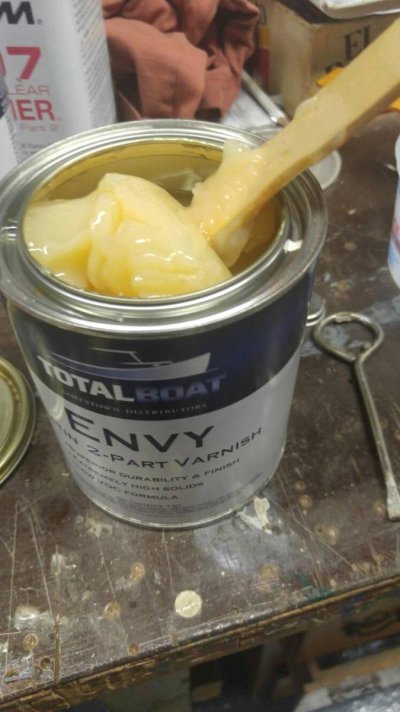

So I decided to go with Total boat Envy two part poly varnish. I ordered it and it took two weeks to arrive from Jamestown. When it arrived it was clumpy, as you can see from the picture. I mixed it with a drill and it improved but it had solids in it and I can't risk it. Luckily after calling Jamestown They are sending me a new can. They said it probably froze. Just more delays[emoji41].

PMF1984

Guru

I tried Envy and loved it going on and the final finish. 18 months later in the sun I am extremely disappointed. I have to strip it off and will be using AllWood.

fryedaze

Guru

- Joined

- Sep 4, 2011

- Messages

- 1,722

- Location

- USA

- Vessel Name

- Fryedaze

- Vessel Make

- MC 42 (Overseas Co) Monk 42

Do you think I will have problems if it is indoors?I tried Envy and loved it going on and the final finish. 18 months later in the sun I am extremely disappointed. I have to strip it off and will be using AllWood.

Pack Mule

TF Site Team

- Joined

- Jan 24, 2013

- Messages

- 3,749

- Location

- USA

- Vessel Name

- Slo-Poke

- Vessel Make

- Jorgensen custom 44

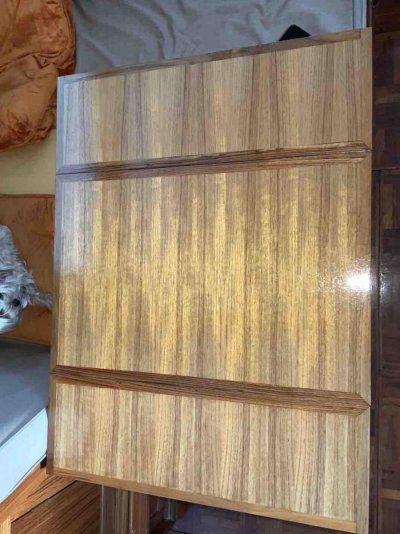

Man that’s a bummer. We’ve used some of their paint and been sorta pleased with it. We’ve never tried their varnish. You’ve got so much work into this project that it’s not worth the chance. The table is beautiful.So I decided to go with Total boat Envy two part poly varnish. I ordered it and it took two weeks to arrive from Jamestown. When it arrived it was clumpy, as you can see from the picture. I mixed it with a drill and it improved but it had solids in it and I can't risk it. Luckily after calling Jamestown They are sending me a new can. They said it probably froze. Just more delays[emoji41].View attachment 105087View attachment 105088

Last edited:

PMF1984

Guru

About the indoors. I do have an interior piece that still looks great. I still have a can of Envy, so I’ll probably use it on those areas that don’t see the sun. I’m more of a fan of a matte or satin finish inside the boat, so I just did some interior work with AllWood Clear Matte.

SeaMoose

Senior Member

- Joined

- Oct 7, 2007

- Messages

- 360

- Vessel Name

- Sea Moose

- Vessel Make

- 1976 34' D/C Taiwanese Trawler

- Joined

- Nov 8, 2012

- Messages

- 2,315

- Location

- USA

- Vessel Name

- Sandpiper

- Vessel Make

- Bluewater 40 Pilothouse Trawler

View attachment 105174

Interlux perfection on mine, 4 coats sprayed. Crazy expensive, you waste a lot... But I’m happy.

I was contemplating durabak floor finish, anybody ever tried that? Goes on with a rag, hard as nails.

That looks great. What type of gun did you shoot the Perfection with?

fryedaze

Guru

- Joined

- Sep 4, 2011

- Messages

- 1,722

- Location

- USA

- Vessel Name

- Fryedaze

- Vessel Make

- MC 42 (Overseas Co) Monk 42

Project almost complete. Table went together well and the lift mechanism work well. The finish is poor. I chose to use the high gloss finish with the plan to soften when done. My garage is too dusty and the varnish did not level well, even with 10% thinning. Going to give it two weeks to get rock hard and then I will fix the finish. It has two coats of epoxy and four coats 2 part Urethane Varnish.

- Joined

- Apr 15, 2008

- Messages

- 13,731

- Location

- California Delta

- Vessel Name

- FlyWright

- Vessel Make

- 1977 Marshall Californian 34 LRC

fryedaze

Guru

- Joined

- Sep 4, 2011

- Messages

- 1,722

- Location

- USA

- Vessel Name

- Fryedaze

- Vessel Make

- MC 42 (Overseas Co) Monk 42

Stick a fork in this one finally. We let the 2 part Urethane cure for two weeks. The finish had dust nibs and brush strokes. The urethane should have been thinned more, even though the directions said it wasn't needed. Wet sanded with 220,320,400,600,1000,1500,2500 and then machine buffed with Finesette. Finish is flat now. Can not wait to get it on the boat and gain all that extra salon space. Thanks for the help TF.

- Joined

- Apr 15, 2008

- Messages

- 13,731

- Location

- California Delta

- Vessel Name

- FlyWright

- Vessel Make

- 1977 Marshall Californian 34 LRC

Hubba hubba!! That looks GREAT!

Similar threads

- Replies

- 3

- Views

- 695