albinalaska

Veteran Member

- Joined

- Jun 6, 2020

- Messages

- 94

- Location

- USA

- Vessel Name

- Sea Gypsy

- Vessel Make

- 1979 Albin Trawler 36'

‘Ello all-

Have been getting into our lazarette (previous posts on my page) and that work has lead to some ideas of reconfiguring our wet exhaust system to ensure less water back-flow issues moving forward.

We’re looking at removing the check valves on the exhaust as I’ve read about a plethora of issues with seizing and with the lack of future accessibility in this area we would like to look at some changes.

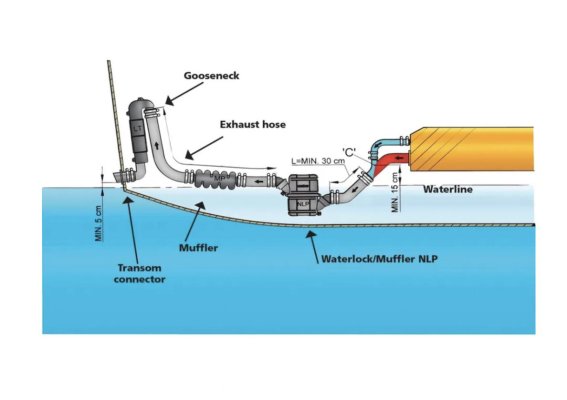

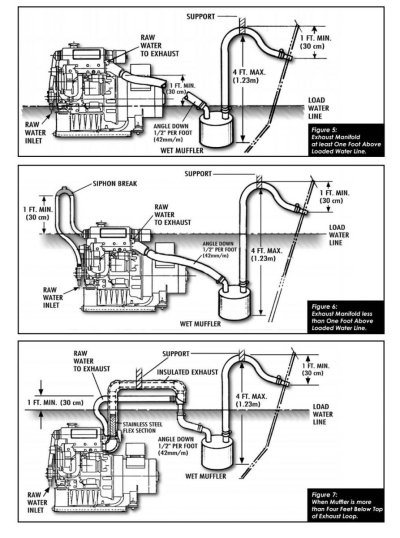

Focusing on eliminating the threat of water back-flow we’re wondering if installing an anti siphon setup in the lazarette is the right move for us. Our engines are just below the waterline, go to a water-lift in the aft cabin and then exit the vessel through the lazarette (obviously) with some old check valves in the way (that we’d like to remove). The exhaust hose runs right along the waterline so that leaves to some ambiguity for us as to our options; any help is appreciated.

If we can install some anti siphon valves that would be the easiest option but we’re open to whatever gets it done right.

Based on some diagrams I’ve researched this seems like a viable option but I know a lot more people have more experience than we do with these systems. Again, Any input is appreciated!

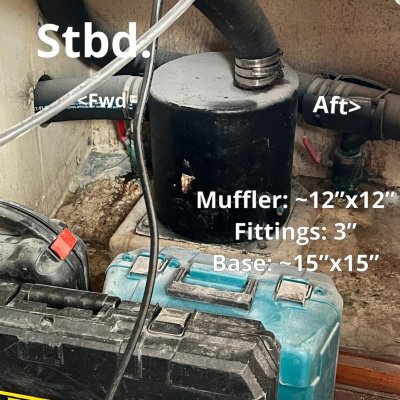

I’ll attach some photos so show the lazarette to show the ample room for an anti siphon option. The water tanks we’re replacing can be modified to work around this hypothetical exhaust system.

Any issues we should be looking at or any reason we shouldn’t do this?

Thank you immensely!

Have been getting into our lazarette (previous posts on my page) and that work has lead to some ideas of reconfiguring our wet exhaust system to ensure less water back-flow issues moving forward.

We’re looking at removing the check valves on the exhaust as I’ve read about a plethora of issues with seizing and with the lack of future accessibility in this area we would like to look at some changes.

Focusing on eliminating the threat of water back-flow we’re wondering if installing an anti siphon setup in the lazarette is the right move for us. Our engines are just below the waterline, go to a water-lift in the aft cabin and then exit the vessel through the lazarette (obviously) with some old check valves in the way (that we’d like to remove). The exhaust hose runs right along the waterline so that leaves to some ambiguity for us as to our options; any help is appreciated.

If we can install some anti siphon valves that would be the easiest option but we’re open to whatever gets it done right.

Based on some diagrams I’ve researched this seems like a viable option but I know a lot more people have more experience than we do with these systems. Again, Any input is appreciated!

I’ll attach some photos so show the lazarette to show the ample room for an anti siphon option. The water tanks we’re replacing can be modified to work around this hypothetical exhaust system.

Any issues we should be looking at or any reason we shouldn’t do this?

Thank you immensely!