PocketAces

Veteran Member

- Joined

- Dec 25, 2019

- Messages

- 45

- Location

- Canada

- Vessel Name

- Pocket Aces

- Vessel Make

- Mainship 34T '08

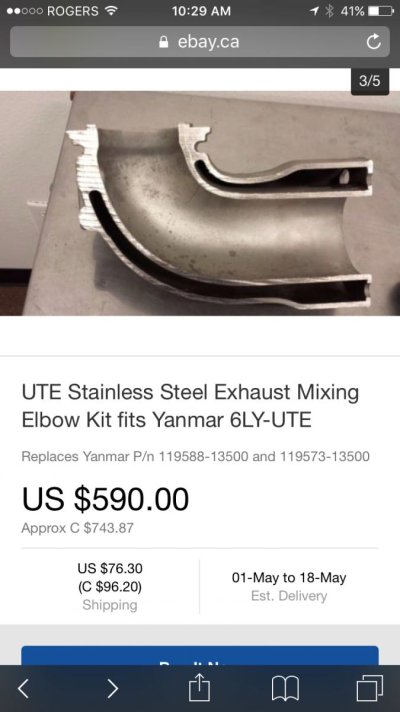

I have a 2008 Mainship 34T. Engine is Yanmar 6LYSTP. So age is 13 years and hours is 1630. in 2018, I noticed rust spots on top of the exhaust elbow. (Pic 1) This suggested that the elbow had corroded and could be due for replacement. So I opened the elbow and the inside looked really good. (Pic 2) At that time, I posted on Mainship Yahoo forum and the feedback was that if the elbow was stainless steel it should have a much longer life than a cast iron elbow. So I painted over the spots and decided to wait...

Fast forward 2 1/2 years and the rust spots are back ( but not that bad - Pic 4). So this time I sanded the spots to see if the rust is superficial or not. To me it looks like the rust is superficial as the sanding seemed to remove everything. (Pic 5) I have painted over and plan to wait another year or two.

So I am wondering if others have seen similar behavior or superficial vs through rusting? If I talk to the local dealer I am sure he would convince me to replace the elbow (and they could do the work). If I leave it, I have the impression that any failure would be gradual not catastrophic? I have seem mention of 2000 hours as a reasonable life for an elbow, so 1600 should be good for another 3-5 years?

Attached pics a) April 2018, b) Inside April 2018, c) reference cross section d) Jan 21 and e) Jan 21 after sanding. Any feedback or thoughts welcome.

Fast forward 2 1/2 years and the rust spots are back ( but not that bad - Pic 4). So this time I sanded the spots to see if the rust is superficial or not. To me it looks like the rust is superficial as the sanding seemed to remove everything. (Pic 5) I have painted over and plan to wait another year or two.

So I am wondering if others have seen similar behavior or superficial vs through rusting? If I talk to the local dealer I am sure he would convince me to replace the elbow (and they could do the work). If I leave it, I have the impression that any failure would be gradual not catastrophic? I have seem mention of 2000 hours as a reasonable life for an elbow, so 1600 should be good for another 3-5 years?

Attached pics a) April 2018, b) Inside April 2018, c) reference cross section d) Jan 21 and e) Jan 21 after sanding. Any feedback or thoughts welcome.