You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

epoxy+varnish over old rough teak?

- Thread starter timb

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

timb

Guru

- Joined

- Sep 12, 2017

- Messages

- 572

- Location

- usa

- Vessel Name

- true heading

- Vessel Make

- marine trader 38 dc

ok I have new 220 sander belts(it works now and I can defiantly ruin wood with it) and I have cleaned everything except the mast .

and I have cleaned everything except the mast .

I also have started considering painting the mast boom and later the window frames after watching some YouTube videos by winty and others. I don't think I will be able to keep up with all the varnish.(I work a lot)

so has anyone used west system with the 207 hardener then a good long lasting paint over the teak.(maybe awgrip) .

I may try Lepke's way on the front floor sections. if it turns out ok then the Samson post and pulpit .

I may have to put seadeck step pads on the steps . they need some kind of finish as they look rough.

thanks for the help everyone.

and I have cleaned everything except the mast .

and I have cleaned everything except the mast .I also have started considering painting the mast boom and later the window frames after watching some YouTube videos by winty and others. I don't think I will be able to keep up with all the varnish.(I work a lot)

so has anyone used west system with the 207 hardener then a good long lasting paint over the teak.(maybe awgrip) .

I may try Lepke's way on the front floor sections. if it turns out ok then the Samson post and pulpit .

I may have to put seadeck step pads on the steps . they need some kind of finish as they look rough.

thanks for the help everyone.

C lectric

Guru

If you even think you will ever want the teak back then put two or three coats of varnish on. Then paint.

If you paint directly you will almost never get the paint out of the grain.

I'm faced with a similar project this coming year. I varnished my salon side windows last season but ran out of time. I have the paint and this season I will paint over the varnish. I put in just about 200 hrs last season and have decided that is too much, thus the paint to ease the work load somewhat.

If you paint directly you will almost never get the paint out of the grain.

I'm faced with a similar project this coming year. I varnished my salon side windows last season but ran out of time. I have the paint and this season I will paint over the varnish. I put in just about 200 hrs last season and have decided that is too much, thus the paint to ease the work load somewhat.

HopCar

Guru

- Joined

- Aug 20, 2011

- Messages

- 5,308

- Vessel Name

- Possum

- Vessel Make

- Ellis 28

What C lectric says makes sense to me but if you use varnish as the base coat, don’t put Awl Grip or similar 2 part polyurethanes over it. They will lift it and make a mess. I don’t know what would happen if you put an epoxy primer over the varnish.

I don’t like two part polys on wood anyway. They are not very flexible and tend to crack at each joint of the wood. I recommend a one part poly like Interlux Briteside.

Using the West 105/207 might stabilize the wood enough that you could use a 2 part poly without getting cracks but I don’t know anyone who has done that..

If you decide to brush a 2 part poly, I recommend Interlux Perfection. It’s easier to brush or roll than Awl Grip. If you spray, use Awl Grip.

I don’t like two part polys on wood anyway. They are not very flexible and tend to crack at each joint of the wood. I recommend a one part poly like Interlux Briteside.

Using the West 105/207 might stabilize the wood enough that you could use a 2 part poly without getting cracks but I don’t know anyone who has done that..

If you decide to brush a 2 part poly, I recommend Interlux Perfection. It’s easier to brush or roll than Awl Grip. If you spray, use Awl Grip.

DHeckrotte

Guru

Surprise, surprise, I've done the paint-over-epoxy, too. Gives a dandy waterproof 'primer' for paint. Again, you really have to 'encapsulate' the wood to get the desired result.

I misspoke in post 18, the shower door, sill and frame was coated out in West epoxy. I put layer of light 'glass cloth on the sill to make the cedar more resistant to foot traffic. I used Brightside Polyurethane directly on the epoxy. (pics too lousy to share.)

I used 'glass and epoxy to repair the painted wood 'pushpit' on our Morgan 27 before I painted it with the Brightside Polyurethane. (That repair was done in about 1998 and I'll bet it hasn't been repainted in this pic taken by her current owner this summer.)

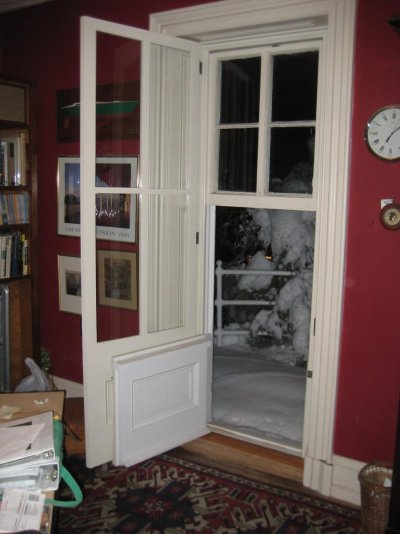

I also made a 'gib' door in 2006, coated out in West epoxy and painted with exterior grade latex house paint. The 'gib' door is the hinged panel under the window which opens normally; you have to duck under. I also made the interior storm door, but it's not in the weather so is simply painted.

I misspoke in post 18, the shower door, sill and frame was coated out in West epoxy. I put layer of light 'glass cloth on the sill to make the cedar more resistant to foot traffic. I used Brightside Polyurethane directly on the epoxy. (pics too lousy to share.)

I used 'glass and epoxy to repair the painted wood 'pushpit' on our Morgan 27 before I painted it with the Brightside Polyurethane. (That repair was done in about 1998 and I'll bet it hasn't been repainted in this pic taken by her current owner this summer.)

I also made a 'gib' door in 2006, coated out in West epoxy and painted with exterior grade latex house paint. The 'gib' door is the hinged panel under the window which opens normally; you have to duck under. I also made the interior storm door, but it's not in the weather so is simply painted.

Attachments

what_barnacles

Guru

I came across this today about cetol, handy reading.

https://www.google.com/url?sa=t&rct...ne-guide.pdf&usg=AOvVaw27bz4cDK7-gaPDc98hO08U

https://www.google.com/url?sa=t&rct...ne-guide.pdf&usg=AOvVaw27bz4cDK7-gaPDc98hO08U

sean9c

Guru

You're not going to glue all those joints, on that grate, together with epoxy or anything else, well enough that you keep moisture out. So water is getting under your finish. Just clean and oil it with some sort of teak oil and be done with it.

On that mast if you varnish it, no matter what you put under the varnish, if it's out in the weather you're going to have to re-varnish it every couple of years. Fine if that's OK with you. If you just want it to still look like wood use Cetol or one of those sorts of wood finishes , it'll last longer.

I'd paint the mast, a good marine enamel would last 4-5 years.

On that mast if you varnish it, no matter what you put under the varnish, if it's out in the weather you're going to have to re-varnish it every couple of years. Fine if that's OK with you. If you just want it to still look like wood use Cetol or one of those sorts of wood finishes , it'll last longer.

I'd paint the mast, a good marine enamel would last 4-5 years.

Delfin

Grand Vizier

- Joined

- Jan 20, 2010

- Messages

- 3,821

For my knowledge what is the benefit of varnish over epoxy vs 7 coats (or whatever the number) of varnish? What does epoxy bringing?

L

Varnish can fail from the top down due to dings or UV deterioration, or from the bottom up from wood movement or moisture. The epoxy simply seals the wood very effectively and gives a slightly harder subsurface than without. Dings in the varnish can admit moisture, but epoxy also helps to prevent that since the water can't soak into the wood.

Epoxy doesn't reduce the number of coats of varnish you need, it just makes what you put on last longer. Epoxy will turn lighter with exposure to the sun so it needs to be protected just like the wood. But if you do have to remove the finish, removing a thinned coat of epoxy is no harder than removing varnish, if you use a heat gun and scraper.

I stopped applying varnish only to wood about 30 years ago for those reasons, with a few exceptions, and I regret the exceptions.

timb

Guru

- Joined

- Sep 12, 2017

- Messages

- 572

- Location

- usa

- Vessel Name

- true heading

- Vessel Make

- marine trader 38 dc

I had to take a little break to install a monitoring system(Siren MTC) so I could sleep at night. and replace a toilet ,and I thank Parks and Peggy for there help. that was an expensive month.

ok I have cleaned , brightened, sanded and oiled the grates and steps . it's ok

now I have decided to epoxy and paint the mast and boom do I need to thin the west system and do I need to prime the epoxy before the Brightsides paint?

also I'm thinking of using fast hardener so I don't have to keep my garage above 65 degrees. is this ok?

thanks for the advise so far.

ok I have cleaned , brightened, sanded and oiled the grates and steps . it's ok

now I have decided to epoxy and paint the mast and boom do I need to thin the west system and do I need to prime the epoxy before the Brightsides paint?

also I'm thinking of using fast hardener so I don't have to keep my garage above 65 degrees. is this ok?

thanks for the advise so far.

RT Firefly

Enigma

Greetings,

I don't know if this has been mentioned yet but IF one uses West System, the amine blush must be removed before re-coating. I have stopped using WS for this reason. MAS, evidently does not have this problem. https://masepoxies.com/

I don't know if this has been mentioned yet but IF one uses West System, the amine blush must be removed before re-coating. I have stopped using WS for this reason. MAS, evidently does not have this problem. https://masepoxies.com/

Delfin

Grand Vizier

- Joined

- Jan 20, 2010

- Messages

- 3,821

I had to take a little break to install a monitoring system(Siren MTC) so I could sleep at night. and replace a toilet ,and I thank Parks and Peggy for there help. that was an expensive month.

ok I have cleaned , brightened, sanded and oiled the grates and steps . it's ok

now I have decided to epoxy and paint the mast and boom do I need to thin the west system and do I need to prime the epoxy before the Brightsides paint?

also I'm thinking of using fast hardener so I don't have to keep my garage above 65 degrees. is this ok?

thanks for the advise so far.

The oil probably wasn't helpful, but cut the epoxy with MEK to the thickness of water and the oil should pose a problem. Apply one coat, then while the other is still setting, apply a second. Wait a week, then wet sand flat. If you use West System you can go with the 207 hardener which (news flash) produces no amine blush, if you care, which I wouldn't assuming you wet sand before painting. If you're going to all this trouble, you might consider using Perfection paint, not Brightside. The former is a two part and would require no primer before overcoating the epoxied sealed wood, as well as being quite a bit harder and more UV resistant Brightside. I could only get a couple of years out of Brightside before it started getting chalky, but Perfection will go a decade.

timb

Guru

- Joined

- Sep 12, 2017

- Messages

- 572

- Location

- usa

- Vessel Name

- true heading

- Vessel Make

- marine trader 38 dc

I already have the west epoxy and 207 hardener I was thinking of fast hardener so I could get it done before it warms up(I can easily maintain 45 deg in my garage) . I can sand if necessary. I'll check on perfection .I'm trying to get an order in so I can do this next week. I may have help to put it up next weekend.

there was no oil put on these pieces

thanks

there was no oil put on these pieces

thanks

Delfin

Grand Vizier

- Joined

- Jan 20, 2010

- Messages

- 3,821

I already have the west epoxy and 207 hardener I was thinking of fast hardener so I could get it done before it warms up(I can easily maintain 45 deg in my garage) . I can sand if necessary. I'll check on perfection .I'm trying to get an order in so I can do this next week. I may have help to put it up next weekend.

there was no oil put on these pieces

thanks

You will usually get a bit of 'furring' after applying MEK + epoxy, so the sanding will be beneficial. If your temps aren't going to be much higher than 45 degrees, you must use the 205 hardener, so again, wet sanding will be needed.

DHeckrotte

Guru

Important to read the instructions on West System and others, too. The hardener containers give the time/temperature ranges. Faster hardeners usually have higher lower and higher limits than slower. Obviously, faster is more convenient. West does not recommend thinning their epoxy. The thinner leaves the epoxy a little porous and weaker. You don't need primers between the epoxy and Brightside Polyurethane. You do have to get the epoxy clean of the amine blush; it retards the paint and disturbs the bond (ask me how I know...) You do have to get the epoxy clean of amine blush when recoating with more epoxy, too; it disturbs the bond. Of course, you'll be sanding anyway since you won't be able to get the epoxy even snough; there will be thick areas and runs. I file the surfaces smooth and flat before sanding.

Delfin

Grand Vizier

- Joined

- Jan 20, 2010

- Messages

- 3,821

Important to read the instructions on West System and others, too. The hardener containers give the time/temperature ranges. Faster hardeners usually have higher lower and higher limits than slower. Obviously, faster is more convenient. West does not recommend thinning their epoxy. The thinner leaves the epoxy a little porous and weaker. You don't need primers between the epoxy and Brightside Polyurethane. You do have to get the epoxy clean of the amine blush; it retards the paint and disturbs the bond (ask me how I know...) You do have to get the epoxy clean of amine blush when recoating with more epoxy, too; it disturbs the bond. Of course, you'll be sanding anyway since you won't be able to get the epoxy even snough; there will be thick areas and runs. I file the surfaces smooth and flat before sanding.

It is true that thinning epoxy weakens it. However, the purpose of penetrating epoxy is to allow it to soak in and seal the wood and provide a base for other coverings. It's hardness in this situation doesn't really matter. It gets hard enough. And once thinned, it soaks in quickly so there aren't runs to deal with.

dkrank

Newbie

Empire is good. I've ordered from them a few times. I also like Red Label. I've found their belts are a bit more expensive, but tend to last longer. Here's the link to their 1/2 x 12" belts:

https://www.redlabelabrasives.com/collections/sanding-belts/1-2-x-12

Also, as a note on shelf life, if the belts were 6 years old it makes sense that they broke. From my understanding, the adhesive used to hold the belts together typically lasts 2-3 years. Anything over that and you're increasing the chances of a snap. Same with storage. If they're in a very humid location that can also take a toll on the adhesive. Belt breakage is a very common issue in Florida and many other Southern states for that reason.

https://www.redlabelabrasives.com/collections/sanding-belts/1-2-x-12

Also, as a note on shelf life, if the belts were 6 years old it makes sense that they broke. From my understanding, the adhesive used to hold the belts together typically lasts 2-3 years. Anything over that and you're increasing the chances of a snap. Same with storage. If they're in a very humid location that can also take a toll on the adhesive. Belt breakage is a very common issue in Florida and many other Southern states for that reason.

Similar threads

- Replies

- 18

- Views

- 1K