whistlerxc

Member

- Joined

- Apr 15, 2021

- Messages

- 13

- Vessel Name

- Salish C

- Vessel Make

- 28' Pelagic Trawler

I know that this topic has been covered probably many times before, but I can't seem to find a reference to my specific question. I drained what I thought was all the coolant from my Perkins Sabre and then proceeded to add fresh coolant. My new coolant is a different color (red vs. the old coolant- green) but meets specs. for my engine. But now i see that I must not have drained ALL the old coolant as I can only add about 15L when capacity is 25L. The result I guess is that I have a mixture of green (unknown kind as this is a new boat to me) and red.

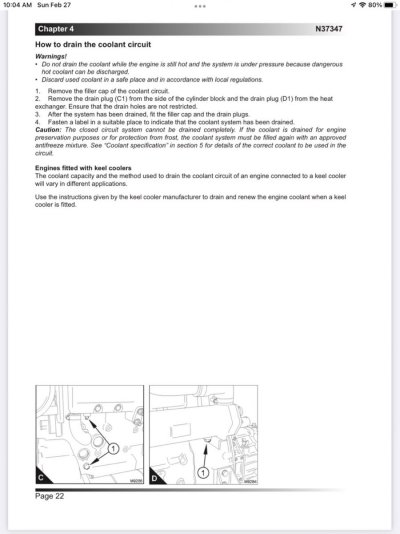

Is this a problem? And is anyone familiar with the Perkins Sabre M135? I drained the heat exchanger as it appeared to be the lowest point. Is there another drain plug that I am missing?

Is this a problem? And is anyone familiar with the Perkins Sabre M135? I drained the heat exchanger as it appeared to be the lowest point. Is there another drain plug that I am missing?