Here is one opinion that I found agrees with many "experienced yards" and "glass experts" in and out of the boat business... and especially for those that think blisters (etc) are only cosmetic.

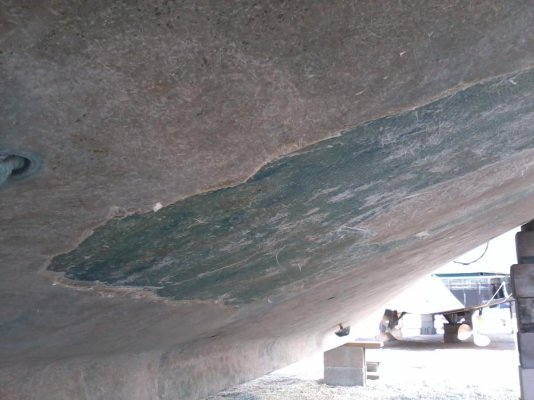

"In real life, we are starting to see failures in hull bottoms we think are directly related to

hydrolysis damage to laminate resin. In six separate cases, we have seen serious, though

the hull fractures at the keel roots on fin keeled sail boats. In each case, the laminate resin

was severely hydrolyzed. We have seen two cases of laminate fracture across bulkhead

hard spots in two powerboats which we thought were related to hydrolysis of the laminate

resin. The good news is that eight boats is not a lot of boats, but consider that these are

only the ones that we have seen. Surely there are more out there and surely there have

been boats lost for these reasons as well. Accident investigation on sunk boats is not like

aircraft crash investigation. Unless the boat is in the way, it is usually not raised and the

cause of sinking investigated.

We can suppose a lot from these tests and experiences, but we still cannot establish

specific strength data for an individual boat in the field.

Suffice it to say that hydrolysis

weakens the bottom and we are seeing failures. This alone should be sufficient reason to

undertake repairs to hydrolyzed laminates as preventative maintenance as soon as

possible."

https://fiberglassatlanta.com/webdocs/blisters.pdf