OP asked for options and costs. In my opinion Lepke gave the best answer regarding options in post #54. Costs guesstimates have been given by many. Unless backed by real experience with wooden boats they are nearly meaningless. Even with real wood boat experience cost estimates will be to a large extent wild guesses. You simply won't know what you're getting into until you start taking her apart. Cofer gave the advice to go into the project with clearly defined priorities and stick to them in post #41. As a young man in the mid 70s I worked at a couple of Seattle area boat yards where all we did was wood. I also owned an 1924 vintage woodie and cared for my father in law's 1940s vintage woodie. Here is what I learned, expressed in % not absolute dollar values.

Restoration cost 390% of purchase price and 7 years of my life. I did the bulk of the work myself.

Sold the boat for 60% of purchase price.

Keep in mind at the time she was "only" 51 yrs old at the start and "only" 58 yrs old when I quit. Your boat is now 84 yrs old.

I have since been associated with a yard that specialized in wood boats and I note some very significant changes since the 70s. All of the old shipwrights are gone. Those were craftsmen of impressive skills, hard working and very efficient at what they did. Hell they'd done for it a life time! The new breed mostly come out of wooden boat schools. Their craftsmanship is of a totally different kind. Slow, meticulous, museum quality work. Where an old shipwright from the 70s would get several planks in in a day, the new ones are lucky to get one plank in in a day.

Another change is the availability of quality boat lumber. It has become insanely expensive.

After restoration you now have routine upkeep. For example bright work. You've provided no pics of or specs of your boat so I went looking for Fellows and Stewart boats and found these two.

M/V Content

Lady Ben

Assuming yours at 65' is more like MV Content you will have two choices. Spend 10$ of thousands of $$$ year on varnish or spend all of your free time varnishing the boat.

As you move through your decision listen to your wallet as much as your heart. You will be forever during your stewardship of the boat replacing wood.

We haven't even touched on systems and machinery. How old are the systems and machinery?

In closing I too love wood boats. They in my opinion are more comfortable, quieter and just plain feel better than boats built of any other material. And I'm a nut to preserve the old. Hull, finishes, fittings, systems. All of it.

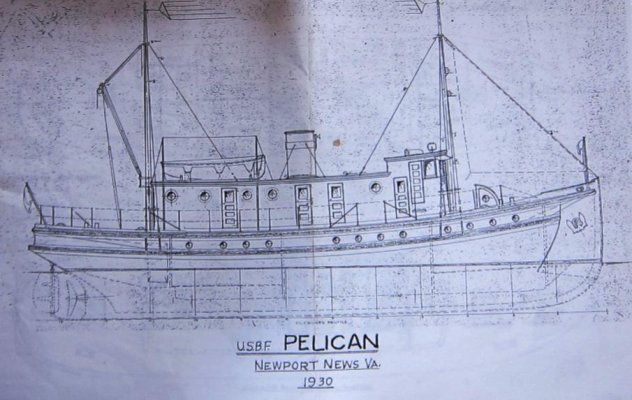

Not too long ago I escaped financial ruin. I fell in love with this one but a local shipwright beat me to the offer by a day. I should send him a sincere thank you.

Edit: Apologies for slighting TDunn who also gave great advice on options.

I am interested in purchasing a 1935 wooden boat 65' that will need hull restoration. I have read about various options, such as marine plywood, 5200, epoxy, fiberglass, etc. Any suggestions, experience, or recommendations, cost estimates?