- Joined

- May 11, 2019

- Messages

- 3,438

- Location

- United States

- Vessel Name

- Muirgen

- Vessel Make

- 50' Beebe Passagemaker

The ABYC propane installation standard is among the shortest in the book, and among the most frequently violated.

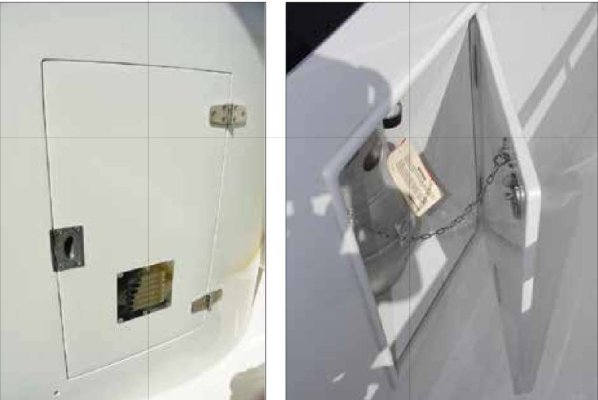

LP lockers can be integral with the vessel, under a settee for instance, provided, among other things, they are top opening and fully gas-tight to the hull interior (this one looks like it has louvers, that's prohibited). There can be no unions or valves in the LP line between the tank and the appliance, with one exception, a transition from pipe to hose as allowed for gimballed stoves. The locker drain must allow gas to flow overboard and discharge away from openings to the hull, portlights or vents for instance.

The requirements, and my recommendations, are summarized here https://stevedmarineconsulting.com/wp-content/uploads/2014/03/LPGas169-02.pdf

I recently conducted an inspection on a trawler, with the owner. When I opened the LP locker I got a faint whiff of gas. I suggested we conduct a leak test. He said, "how do we do that?". "With the leak detector, otherwise known as a pressure gauge", I responded. He was a savvy owner, very mechanically competent, but he had no idea the pressure gauge was designed for this, and only this purpose (contrary to popular belief, it does not measure gas quantity, LP maintains the same pressure regardless of volume).

Using the pressure gauge you should leak test your system monthly. In this case, the gauge could be seen to drop almost immediately, it was a serious leak. Using soapy water, however, we found no leaks in the LP locker, we did find a leak at a valve in the stove top. His wife said to me, "I've bene telling him I smelled something like garbage in this area".

There was a sniffer sensor mounted under the stove, however, it wasn't sounding, I suspect because instead of of being mounted on the deck it was mounted on the bulkhead a couple of inches above the deck. Sensors should also be tested regularly, by allowing gas from a butane lighter (without the flame) to flow into them. I like to have a sensor under the stove and another in the LP locker, again as low as possible and where they can be accessed for testing.

Steve, I've always wondered about the portion highlighted in RED above. Doesn't this preclude the use of electrically actuated propane shutoff valves since it consists of two additional connections, or unions, one on each side of the solenoid valve, as well as being an actual valve in itself?