Simi 60

Guru

- Joined

- Jul 1, 2016

- Messages

- 5,482

- Location

- Australia

- Vessel Make

- Milkraft 60 converted timber prawn trawler

Has anyone actually measured the loads when underway of paravanes in action?

I know in Beebes book it was made mention of around 3 ton but I'm starting to think that can't be right

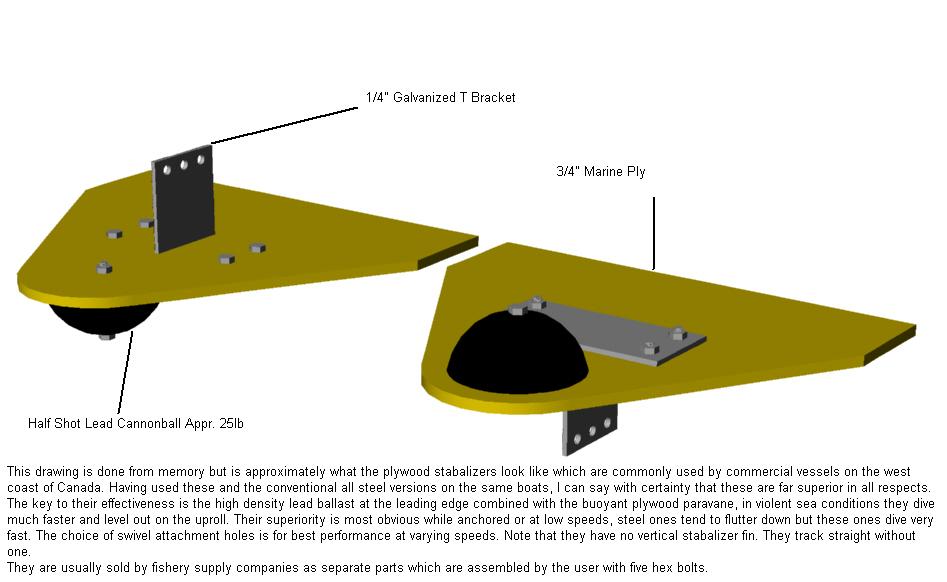

Reason I say this is because of the plywood paravanes

This being one

And another

From this thread

https://www.trawlerforum.com/forums/s31/paravanes-vs-sea-gyro-vs-active-fins-5870.html

My thinking would be if there was 3 ton of load, so 1.5 ton of load either side of the centreline of 3/4 inch plywood fish, it'd collapse

Thoughts?

I know in Beebes book it was made mention of around 3 ton but I'm starting to think that can't be right

Reason I say this is because of the plywood paravanes

This being one

And another

From this thread

https://www.trawlerforum.com/forums/s31/paravanes-vs-sea-gyro-vs-active-fins-5870.html

My thinking would be if there was 3 ton of load, so 1.5 ton of load either side of the centreline of 3/4 inch plywood fish, it'd collapse

Thoughts?