Snapdragon III

Senior Member

- Joined

- Sep 1, 2016

- Messages

- 421

- Location

- USA

- Vessel Name

- Snapdragon

- Vessel Make

- Custom 56' Skookum trawler

Your system looks great. Just one off the wall question. Have you ever considered running your coolant for the heating system through your closed loop cooling system on your generator to use the heat of the engine to heat boat. I have done that on my Boat and I love it. I just don't hear others talking about it. Free heat while the generator is running and when it is not running use the boiler.

John

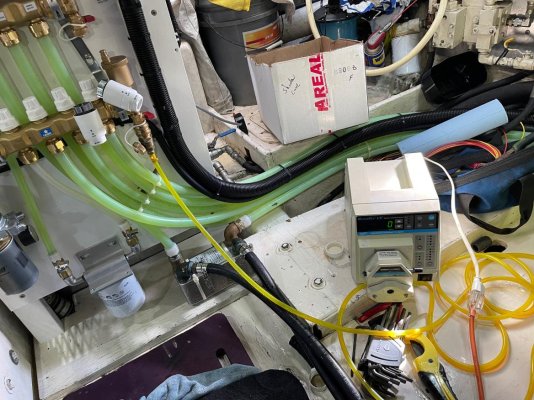

That sounds like a good idea. In my case my boat doesn't have a true generator. It has a DC "Generator" that is an large alternator/watermaker hooked to a little 6hp Kubota engine. It would definitely be possible to tie it into the heating system, but it is pretty small. With the lithium batteries and solar on the boat I hope that I won't have to run the dc generator very much.