skipperdude

Guru

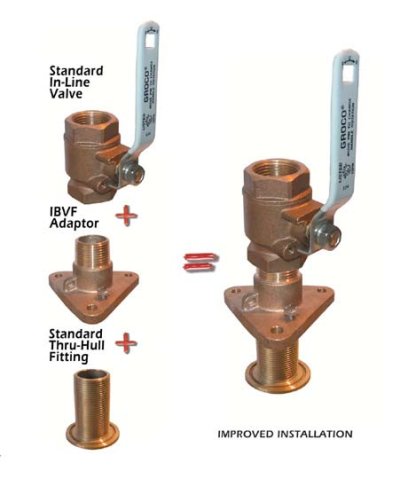

So It is common Knowledge or not so common knowledge that a through hull fitting is straight thread as is a proper Seacock. Ball valves from the local home hard ware store are NPT or tapered.

The two don't work together.

Who has A ball Valve on a through hull in there boat?

I am working on my SAMS marine survey certification.

You would be surprised at how often I find this issue.

SD

The two don't work together.

Who has A ball Valve on a through hull in there boat?

I am working on my SAMS marine survey certification.

You would be surprised at how often I find this issue.

SD